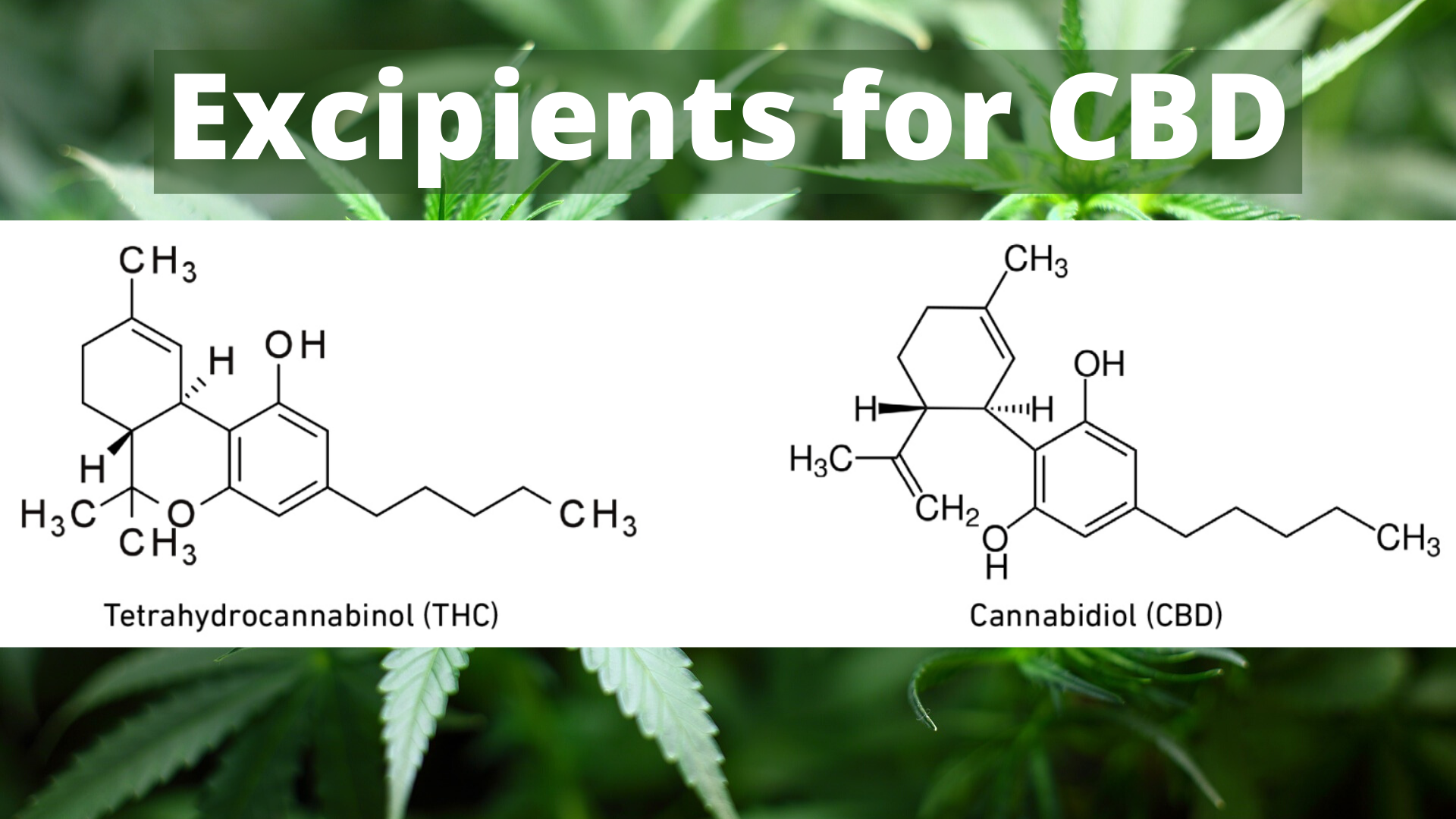

Cannabidiol aqueous solubility enhancement: Comparison of three amorphous formulations strategies using different type of polymers

Poor aqueous solubility of terpenophenolic compound Cannabidiol (CBD) is a major issue in the widespread use of this promising therapeutic polyphenol. Moreover, choosing the appropriate strategy to overcome this challenge is time-consuming and based on trial–error processes. The amorphous form of CBD provided higher aqueous solubility as well as faster dissolution rate in comparison with crystalline CBD. Nevertheless, amorphous forms of CBD tend to recrystallize. The aim of this study was to use three different strategies based on the stabilization of the amorphous form. Cyclodextrins (CH3αCD, HPβCD and HPγCD.), mesoporous silicas (Silsol® and Syloid® AL-1FP) and water soluble polymers (Kollidon® VA64, Kollidon® 12PF and Soluplus®) were processed by using the following techniques: freeze-drying, spray-drying, subcritical carbon dioxide impregnation or hot-melt extrusion. All the obtained formulations provided complete amorphous CBD, although the drug loading depend highly of the excipients. CBD-cyclodextrin formulations, processed by freeze-drying or spray-drying, and CBD-mesoporous silica formulations, processed by subcritical CO2 or by atmospheric impregnation, provided significant increase of aqueous solubility. While the use of Kollidon® 12PF did not provided significant increased solubility within 90 min, Kollidon® VA64 has been highlighted as the excipient that exhibits the highest increase of aqueous solubility of this study. Finally, all formulations, excepted CBD-ALFP formulations, showed adequate stability within at least two months. More on Cannabidiol aqueous solubility enhancement

Keywords Cannabidiol, CBD, Amorphous dispersion, Spray drying, Freeze drying, Hot melt extrusion, Impregnation

See also our special of excipients for CBD