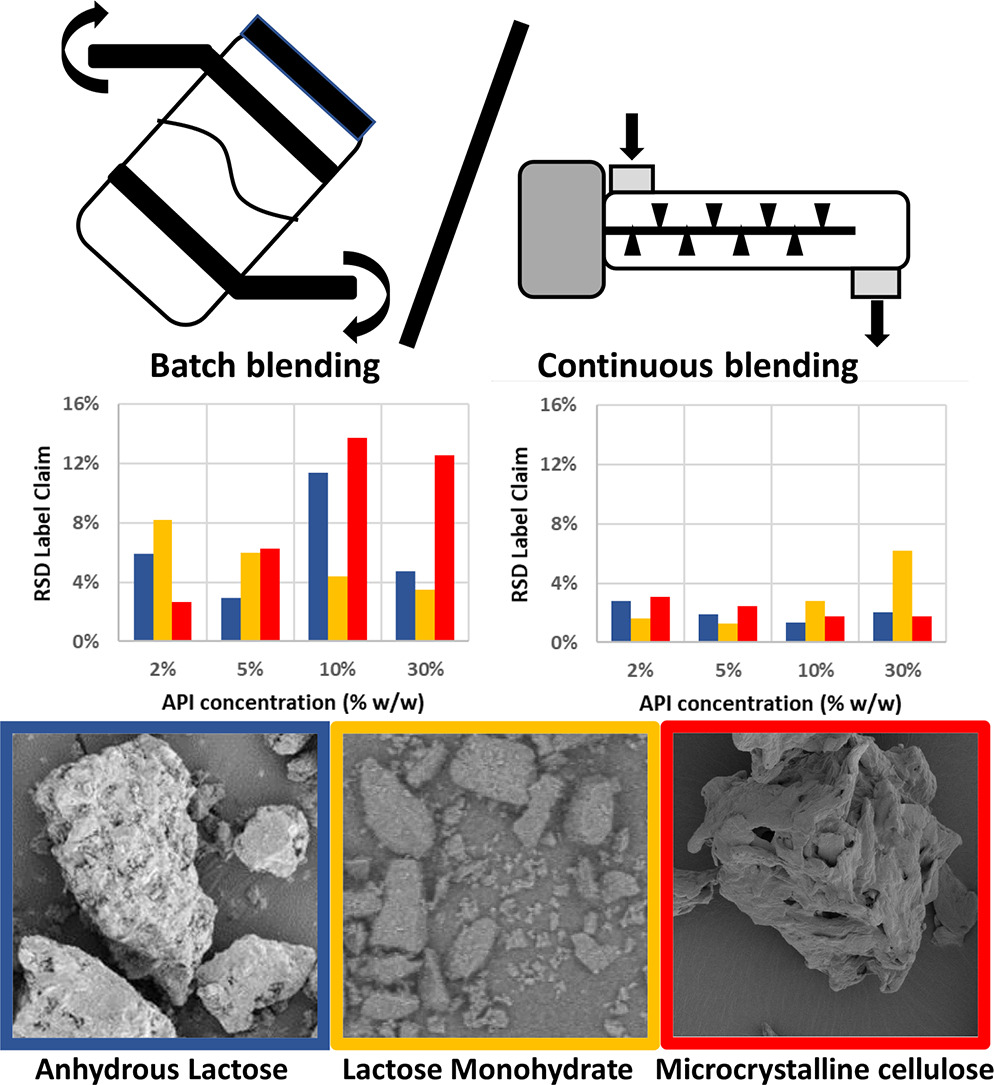

Impact of excipients on batch and continuous powder blending

Stimulated by Pharma 4.0, the pharmaceutical industry is changing from batch-wise to continuous manufacturing. Therefore, individual processing steps such as blending of the active pharmaceutical ingredient (API) with excipients have to be re-designed to continuous operations.

Highlights

Continuous powder blending improves content uniformity of API-excipient blends.

Excipient properties affect batch and continuous powder blending processes.

Consistency of a continuous blending process depends on powder flow properties.

Variation of excipients affects content uniformity upon blending with API.

In this study, batch and continuous powder blending are directly compared for API with three different excipients with varying material properties. Content uniformity analysis of the blends shows that the continuous process results in more homogeneous blends for all excipients, independent of API dosage. The type of excipient used, however does impact the consistency of the continuous blending process over time. The results presented here reveal the impact of the physical material properties of excipients on blending with API in batch and continuous processes. Continue on impact of excipients on batch and continuous powder blending

Keywords Continuous manufacturing, Excipients, Powder mixing, Powder flow, Lactose, Microcrystalline cellulose