Percolation-based simulation to predict caking kinetics of polydisperse amorphous powders

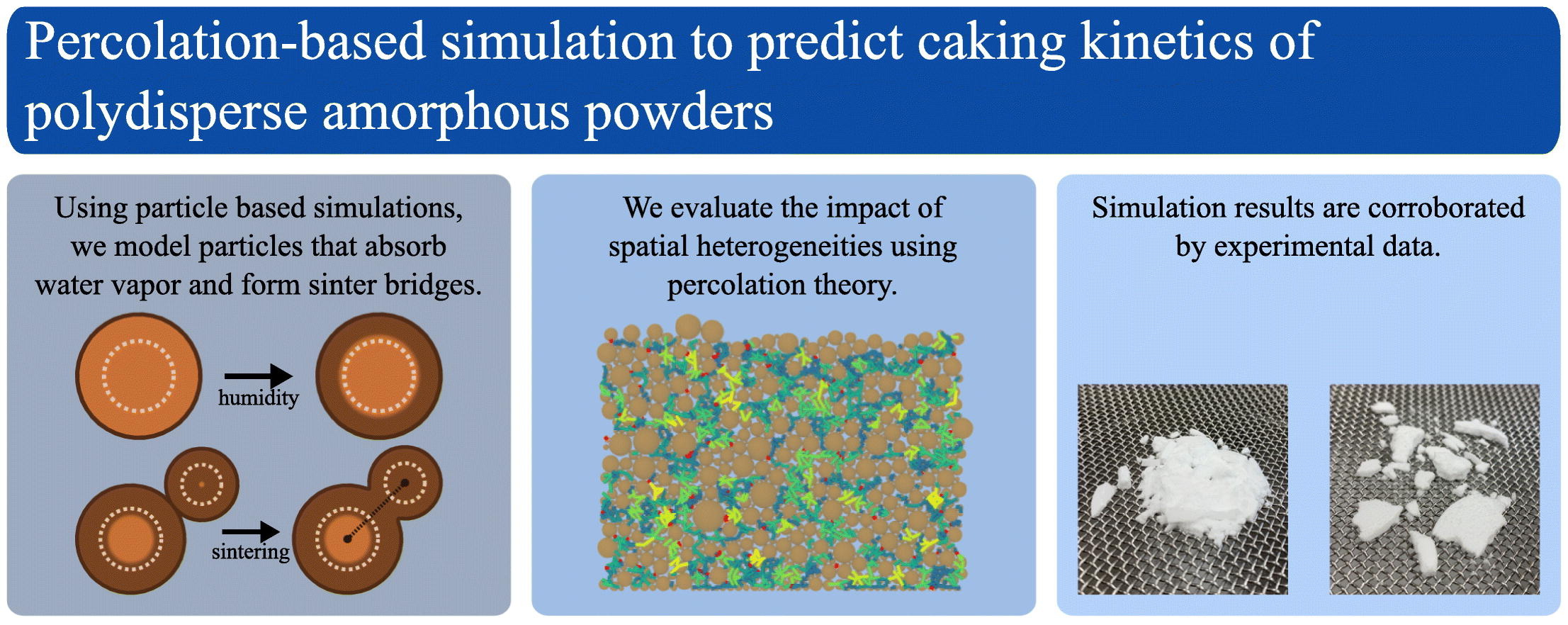

Caking in amorphous powders compromises their quality during storage. Individual particles absorb water vapor, which changes their viscosity and promotes the formation of sinter bridges. Lumps of particles grow and eventually span the whole powder, affecting the mechanical properties and quality of the powder. Previous studies of the caking dynamics largely neglect the role of spatial heterogeneities in the particle-size distribution.

Highlights

• Caking of amorphous powders is studied using a particle-based model

• When the moisture of the sample increases abruptly sintered contacts are formed

• The cacking time is captured by the percolation threshold of the sintered contacts

• The numerical results agree qualitatively with data obtained experimentally

We perform particle-based simulations and show that, if caking is mapped into a percolation transition, the role of spatial heterogeneities is well captured by the corresponding percolation threshold. Since this threshold only depends on the geometry of the granular assembly, we can separate the contribution of the spatial heterogeneities and of the individual particle properties. This enables a rational approach for interpreting and mitigating caking propensity of commercial products consisting of particle species with different particle size distributions. We corroborate the numerical and analytical predictions with experiments.

Continue reading here

About this article: Vasco C. Braz, André F.V. Matias, Laurent Forny, Delphine Pasche, Vincent Meunier, Jan Engmann, Nuno A.M. Araújo, Percolation-based simulation to predict caking kinetics of polydisperse amorphous powders, Powder Technology, 2022, 117248, ISSN 0032-5910, https://doi.org/10.1016/j.powtec.2022.117248. (https://www.sciencedirect.com/science/article/pii/S0032591022001425)