A Quality by Design (QbD) study in direct compression using highly compactible and flowing microcrystalline cellulose CEOLUS™ UF-711

OBJECTIVE

CEOLUSTM UF-711 is highly compactible and flowing microcrystalline cellulose (MCC). While UF-711 has over 1.5 times the compactibility of standard grade PH-102, it has the same flow characteristics as PH-102. This is because the UF-711 particle has a round shape and has many pores inside its particle.

The purpose of this QbD study is to demonstrate that UF-711 has higher robustness than PH-102 by analyzing the impact of formulation and process variables on tablet’s critical quality attributes (CQA) in direct compression of poorly compactible drug.

What is CeolusTM UF-711?

CEOLUSTM UF-711 is an NF/EP/JP compatible MCC.

Powder properties

Tab.1 Powder properties of CEOLUSTM grades:

| Bulk density (g/cm3) | Av.particle diameter (µm) | Repose Angle (o) | |

| UF-711 | 0.22 | 50 | 42 |

| UF-702 | 0.29 | 90 | 34 |

| KG 1000 | 0.12 | 50 | 57 |

| KG 802 | 0.21 | 50 | 49 |

| PH 101 | 0.29 | 50 | 45 |

| PH 102 | 0.30 | 90 | 42 |

Particle morphology

Fig.2 Particle morphology of CEOLUSTM grades:

Fig.3 Relationship between compactibility and flowability of MCC grade:

METHOD

Formulation and Process variables

1) Drug Loading, 2) Lubricant level, 3) Tableting speed.

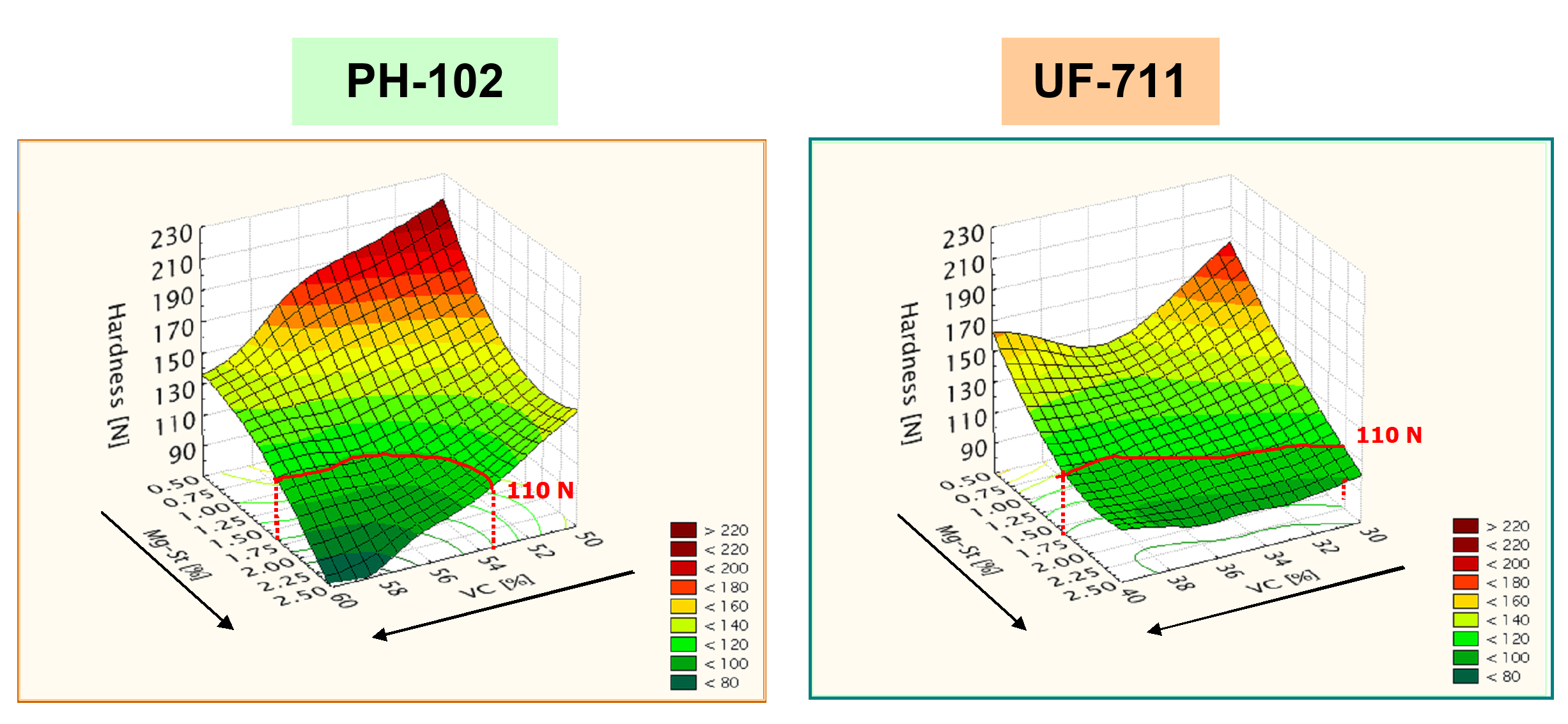

Asahi Kasei compared the robustness between UF-711 and PH-102 by measuring design space, where tablet hardness was over 110 N.

RESULTS

Analysis-1 with fixed Tableting speed (40 rpm):

UF-711: At 50% drug loading, hardness of UF-711 formulations exceeded 110 N even at 2.25% lubricant.

PH-102: Hardness was strongly influenced by lubricant level. Even in case of 30% drug loading, hardness could not reach 110 N at 2.25% lubricant.

Analysis-2 with fixed drug loading level

UF-711/VC50%: Hardness stayed high (over 110 N) at high lubricant level.

PH-102/VC30%: Hardness decreased with increasing lubricant level.

UF-711 had wider design space in spite of drug loading level 20% higher than PH-102.

UF-711 has lower lubricant sensitivity than PH-102.

CONCLUSION

This QbD Study demonstrated that CEOLUSTM UF-711 formulation may contain a larger amount of ascorbic acid and furthermore had higher robustness than PH-102 in direct compression. Highly compactible and flowable MCC CEOLUSTM UF-711 is suitable for direct compression at high drug loading (over 50%) formulation.

REFERENCE

The data of this page is a property of Asahi Kasei Corporation.