Investigation of granular dynamics in a continuous blender using the GPU-enhanced discrete element method

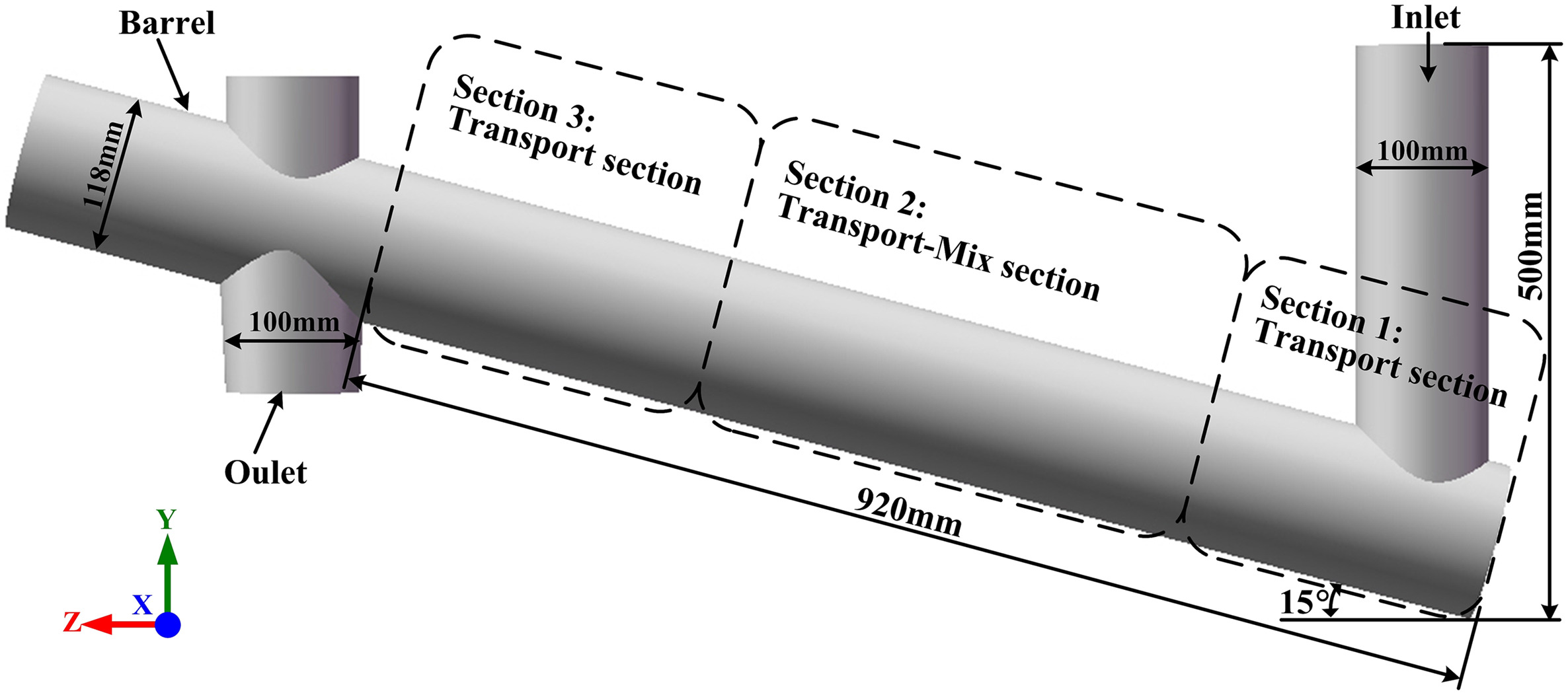

Continuous powder blending is an essential operation during continuous pharmaceutical manufacturing. However, the complex granular dynamics in the blender is still poorly understood. This study employs a graphic processor unit (GPU) enhanced discrete element method (DEM) to analyse the granular dynamics in a continuous blender. Numerical results indicate that only a small fraction of powder distributes in the upper region of the blender, while most of that distributes in the middle and lower regions.

Highlights

• GPU-enhanced DEM analysis on the full-scale continuous blending is performed.

• Impeller speed has a significant impact on the powder flow in the inclined blender.

• At steady-state, powder mainly distributes in the middle and bottom zones of blender.

• Maximum number of blade passes can be achieved at an intermediate impeller speed.

Besides, a higher impeller speed leads to a smaller hold-up mass and a shorter mean residence time. Interestingly, the maximum number of blade passes is achieved at an intermediate impeller speed. There are two distinct regimes during continuous blending: i) a shearing regime at low impeller speeds; and ii) a dynamic regime at high impeller speeds. This study demonstrates that the GPU-enhanced DEM can be a robust tool for analyzing powder flow during continuous pharmaceutical manufacturing.

Download the full article as PDF (“pre-proof”) here Investigation of granular dynamics in a continuous blender using the GPU-enhanced discrete element method

or read it here

Materials

Microcrystalline cellulose (MCC), VIVAPUR® MCC Spheres 1000 (JRS Pharma GmbH & Co. KG, Rosenberg, Germany), is used in this study as the model material. Fig. 2 presents the micro-image of MCC particles using a digital microscope (VHX-7000, Keyence Deutschland GmbH, Neu-Isenburg, Germany). The powder presents a high degree of brightness and excellent sphericity. The ring shear test indicted that the VIVAPUR® MCC Spheres 1000 is a free-flowing powder. Fig. 3 shows the corresponding volume percentage and cumulative particle size distribution. It can be seen that the powder has a narrow size distribution. The mean diameter of the VIVAPUR® MCC Spheres 1000 is about 1197 μm. The true density of the powder is 1450 kg/m3, which is measured with a helium pycnometer (AccuPyc II 1340, Micromeritics, USA).

Chao Zheng, Liang Li, Bernardus Joseph Nitert, Nicolin Govender, Thomas Chamberlain, Ling Zhang, Chuan-Yu Wu, Investigation of granular dynamics in a continuous blender using the GPU-enhanced discrete element method, Powder Technology, 2022, 117968, ISSN 0032-5910, https://doi.org/10.1016/j.powtec.2022.117968