Planetary roller melt granulation (PRMG) – A new continuous method for powder processing

Abstract

For the continuous operation of granulation, which is a standard unit operation in powder processing to modify the particle size, the use of twin-screw machines was established as standard method for wet and melt granulation over the last decade. A main characteristic for this technology is the pronounced mechanical energy input and the coupling of this parameter to the throughput for high throughputs. This is challenging for melt granulation with respect to temperature control and the handling of temperature sensitive materials.

In this respect, the use of a planetary roller granulator is a promising alternative due to the distinctive process concept. Here, planetary spindles within a roller cylinder are circulating around a motor-driven central spindle. These three main parts are interlocking due to a 45°toothing, which results in an enhanced generated surface of the processed material. In addition with the heating concept, which includes the roller cylinder and central spindle, this leads to an enhanced ratio of heated surface to process volume.

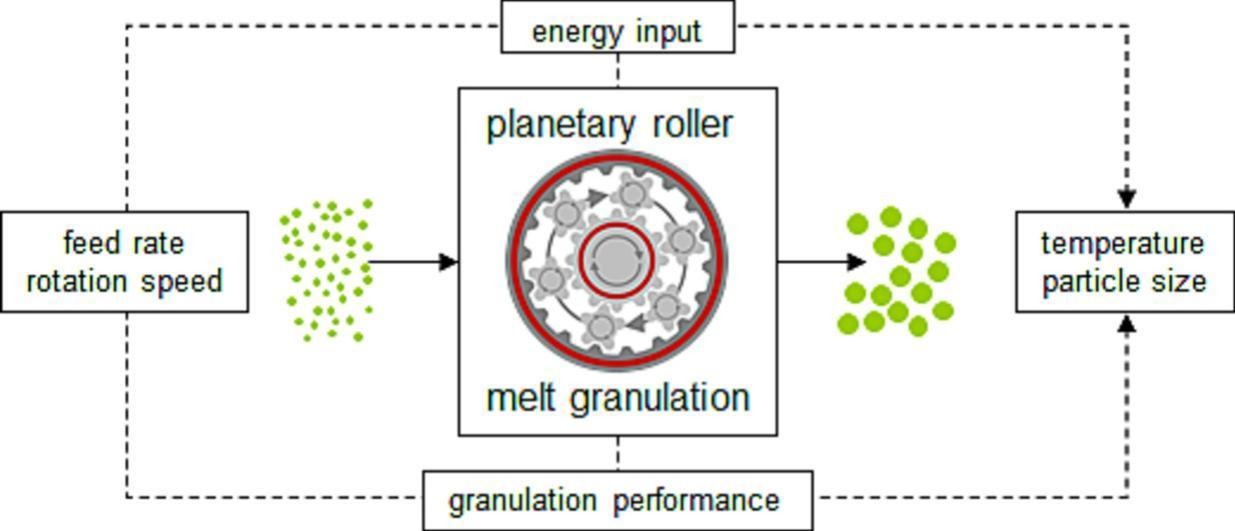

For planetary roller melt granulation (PRMG), the feed rate and rotation speed as direct process parameters are suitable to adjust the mechanical and thermal energy input, while the ratio of these correlates to the product temperature. Therefore, a predictive determination of an operating point in this context is possible by the derived corresponding model. Moreover, the variation of the direct process parameters also impacts the fraction of net granulated particles during PRMG. This is an indicator for a shift in the overall process regime with respect to the fundamental process rates.

Melt granulation

Experiments were conducted on a lab scale granulator (PWE 30, Entex Rust & Mitschke GmbH, Bochum, Germany) with a single module unit as processing section configured with five standard planetary spindles of full length (compare Fig. 1). A model formulation consisting of 10 wt% hydroxypropylcellulose (Klucel EXF Pharm, Ashland Inc., Covington, USA) as meltable binder and lactose monohydrate (Lactose 310, Foremost Farms USA, Baraboo, USA) as model compound was mixed prior with a wheel mixer (RRM…

Read more here

Daniel Nesges, Tom Lang, Thomas Birr, Markus Thommes, Jens Bartsch, Planetary roller melt granulation (PRMG) – A new continuous method for powder processing, Powder Technology, Volume 427, 2023, 118728, ISSN 0032-5910, https://doi.org/10.1016/j.powtec.2023.118728.

Read more on Binder – Pharmaceutical Excipients here: