Selection of lubricant type and concentration for orodispersible tablets

Abstract

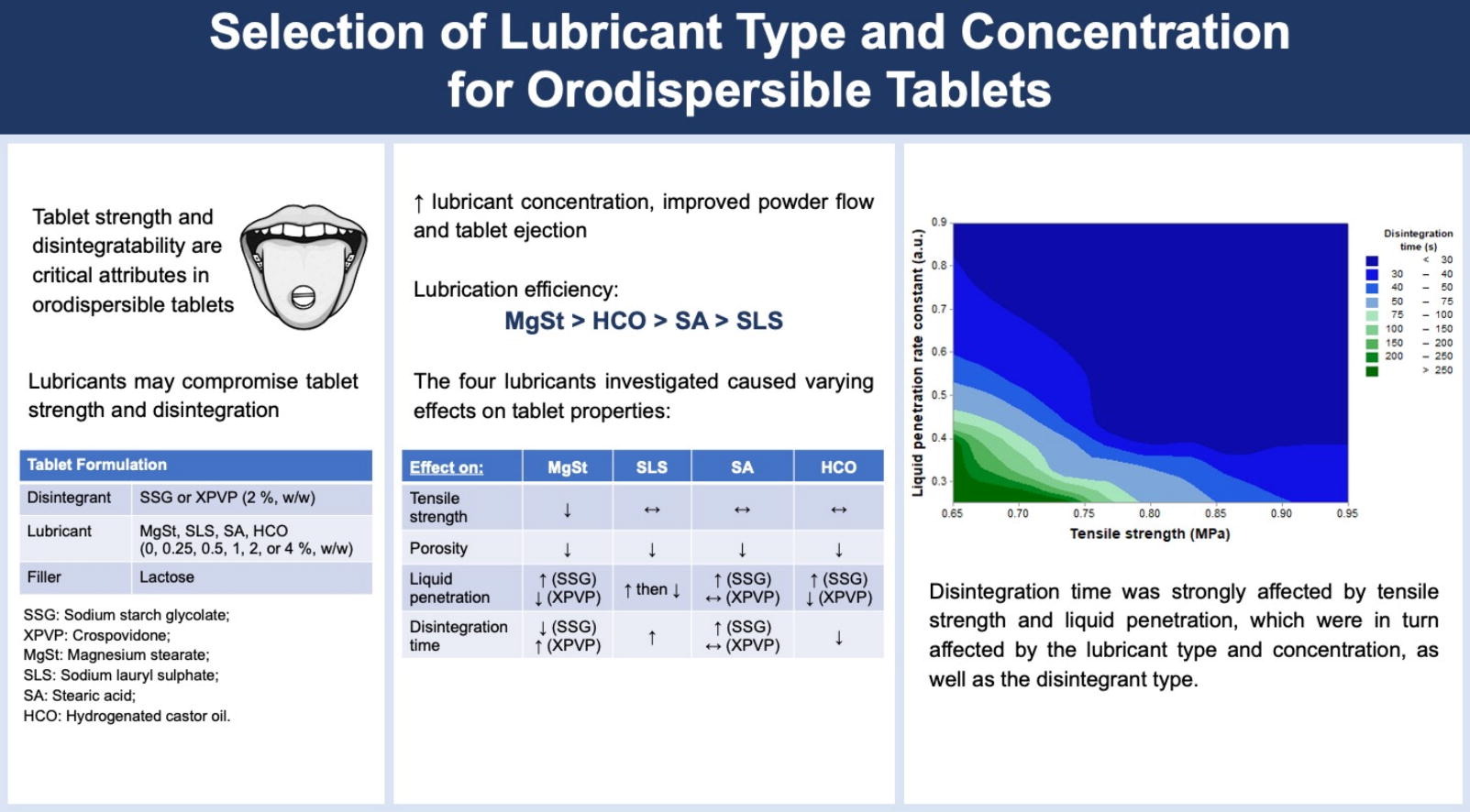

Lubricants are essential for most tablet formulations as they assist powder flow, prevent adhesion to tableting tools and facilitate tablet ejection. Magnesium stearate (MgSt) is an effective lubricant but may compromise tablet strength and disintegratability. In the design of orodispersible tablets, tablet strength and disintegratability are critical attributes of the dosage form. Hence, this study aimed to conduct an in-depth comparative study of MgSt with alternative lubricants, namely sodium lauryl sulphate (SLS), stearic acid (SA) and hydrogenated castor oil (HCO), for their effects on the tableting process as well as tablet properties. Powder blends were prepared with lactose, sodium starch glycolate or crospovidone as the disintegrant, and a lubricant at different concentrations.

Angle of repose was determined for the mixtures. Comparative evaluation was carried out based on the ejection force, tensile strength, liquid penetration and disintegratability of the tablets produced. As the lubricant concentration increased, powder flow and tablet ejection improved. The lubrication efficiency generally decreased as follows: MgSt > HCO > SA > SLS. Despite its superior lubrication efficacy, MgSt is the only lubricant of four evaluated that reduced tablet tensile strength. Tablet disintegration time was strongly determined by tensile strength and liquid penetration, which were in turn affected by the lubricant type and concentration. All the above factors should be taken into consideration when deciding the type and concentration of lubricant for an orodispersible tablet formulation.

Introduction

Tablets are popular and widely used as a dosage form because of their compactness, accurate dosing, stability and cost-effective production (Alderborn and Aulton, 2013, Moreton et al., 2008, Turkoglu et al., 2009). Tablet disintegration refers to the mechanical break-up of the compressed tablet into multiple fragments when it comes into contact with water (Alderborn, 2013). Orodispersible tablets (ODTs) are tablets that disintegrate in the oral cavity, making this dosage form patient-friendly and especially suitable for patients with dysphagia (Al-khattawi and Mohammed, 2013). Disintegrants are important excipients in ODTs to promote tablet break-up and drug dissolution (Moreton, 2008).

Disintegrants exhibit various mechanisms of action, mainly swelling, strain recovery and wicking. Swelling refers to the omni-directional volume expansion of disintegrant particles upon contact with the disintegration medium (Faroongsarng and Peck, 1994, Quodbach et al., 2014). Strain recovery refers to the uni-directional recovery of the compressed disintegrant particles to their original shape (Patel et al., 2007). Sodium starch glycolate (SSG) acts mainly by swelling whereas crospovidone (XPVP) acts mainly via strain recovery. Wicking refers to the process of liquid uptake into the tablet by capillary action (Kissa, 1996, Moreton et al., 2008), providing water that is required for swelling, strain recovery and other disintegrant mechanisms (Moreton et al., 2008, Nogami et al., 1967). Wicking can also weaken the tablet structure by disrupting inter-particle bonds such as hydrogen bonds (Patel and Hopponent, 1966). Disintegrants and other hydrophilic components within the tablet also contribute to liquid penetration by conferring hydrophilicity to the matrix (Shotton and Leonard, 1972).

In the manufacture of ODTs, the direct compression method is preferred due to its cost-effectiveness (Al-khattawi and Mohammed, 2013). Lubricants are required in the tablet formulation to reduce friction between the compact and the die wall and facilitate tablet ejection (Alderborn and Aulton, 2013, Late et al., 2009, Paul and Sun, 2018). The ejection force refers to the force applied by the lower punch to push the compact out of the die and is a useful parameter to measure lubrication efficiency (Sun, 2015). Lubricants also serve as glidants and anti-adherents. Glidants improve powder flow by reducing inter-particle friction, whereas anti-adherents prevent sticking of tablets to punch or die surfaces (Kar et al., 2019).

Magnesium stearate (MgSt) is the most commonly used lubricant due to its high lubrication efficiency. However, the incorporation of MgSt as a lubricant, even at low concentrations, may affect tablet tensile strength, disintegration and dissolution (Chowhan and Chi, 1986, Leinonen et al., 1992, Paul and Sun, 2018, Sun, 2011). This is because of the low bonding strength of MgSt at binding surfaces and the hydrophobic nature of MgSt hindering wetting and liquid penetration into the tablet. MgSt is also incompatible with certain formulations as it interacts with certain drugs and affects drug release or stability (D’Cruz et al., 2018, Stojanovska Pecova et al., 2020). Thus, alternative lubricants may be needed, particularly when designing ODTs where rapid tablet disintegration is required. Sodium lauryl sulphate (SLS) is a hydrophilic lubricant that can attract water and promote liquid penetration into the tablet (Levy and Gumtow, 1963, Wang et al., 2010). SLS is a surfactant that is commonly used to improve drug dissolution. Stearic acid (SA) is the most common lubricant from the class of fatty acids, fatty alcohols and hydrocarbons. However, it has been found to have lower lubrication efficiency compared to metallic salts of fatty acids such as MgSt (Kaji et al., 1985). Hydrogenated castor oil (HCO) has also been investigated for its potential as a tablet lubricant and was reported to affect tablet tensile strength and disintegration less significantly than MgSt (Wang et al., 2010).

The effect of MgSt on the tableting process and tablet properties has been extensively studied but much less for other lubricants. Often, in formulation development, the choice of type and amount of lubricant is made empirically based on formulator’s prior experience and preference (Paul and Sun, 2018). However, the choice is best made through a systematic evaluation process instead. Hence, this study was designed to conduct an in-depth comparison between MgSt with alternative lubricants (SLS, SA and HCO). A full factorial study was employed to examine the effect of lubricant type and concentration on the tableting process and tablet properties.

Read more here

Materials

The lubricants used were magnesium stearate (MgSt; Type E, Faci Asia Pacific, Singapore), sodium lauryl sulphate (SLS; Kolliphor SLS Fine, BASF, Germany), stearic acid (SA; Kolliwax S Fine, BASF, Germany) and hydrogenated castor oil (HCO; Kolliwax HCO, BASF, Germany). Sodium starch glycolate (SSG; Primojel, DFE Pharma, the Netherlands) or crospovidone (XPVP; Kollidon CL, BASF, Germany) was the disintegrant and lactose (Tablettose 100, Meggle, Germany) was the filler for all formulations.

Audrey Yi Zheng, Mahn Teng Loh, Paul Wan Sia Heng, Lai Wah Chan, Selection of lubricant type and concentration for orodispersible tablets, International Journal of Pharmaceutics, 2024, 124190, ISSN 0378-5173, https://doi.org/10.1016/j.ijpharm.2024.124190.

Read also our introduction article on Lubricants here: