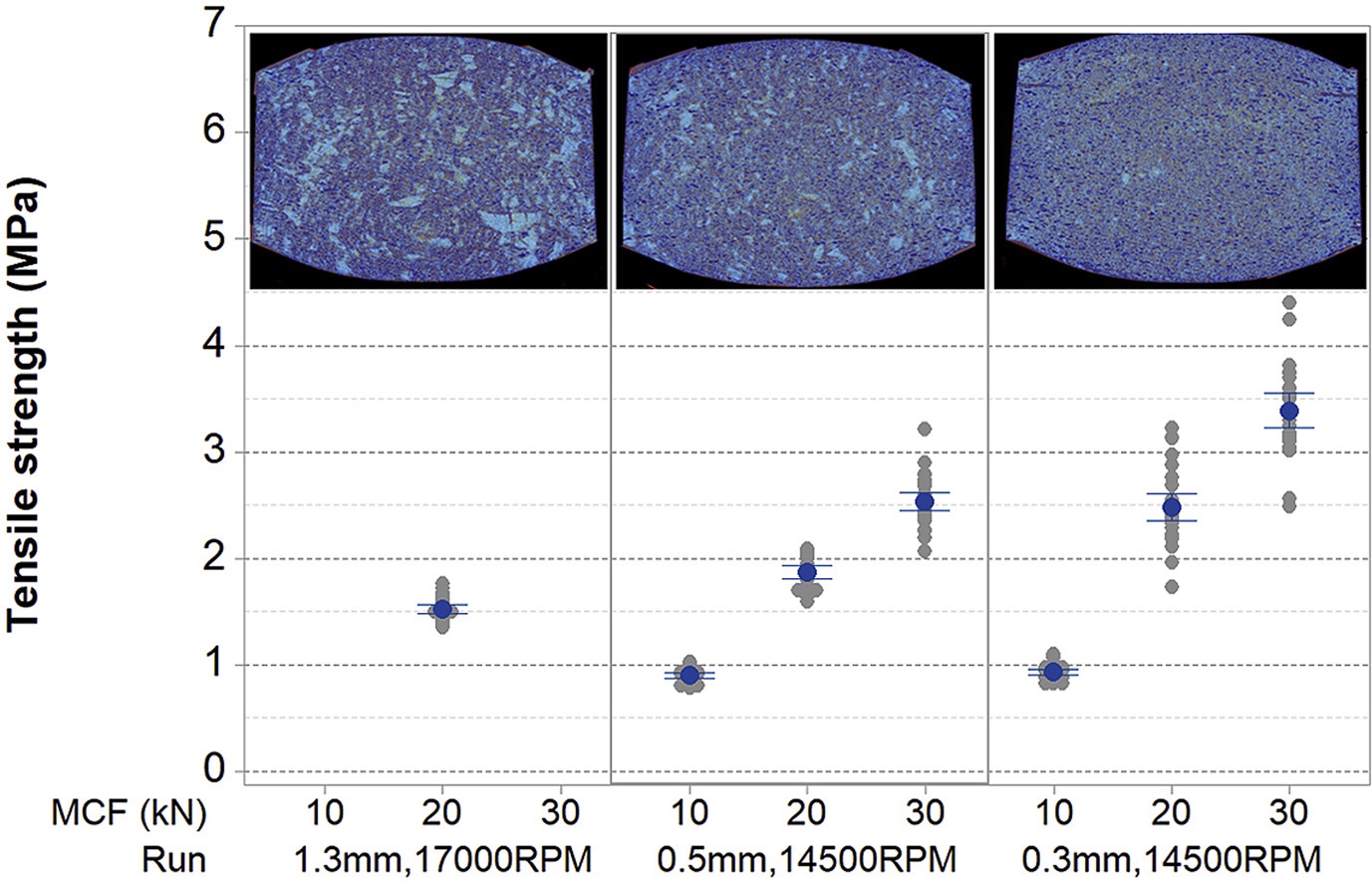

Tablet tensile strength

Increasing tensile strength by reducing particle size for extrudate-based tablet formulations

The effect of milled extrudate particle size on tablet tensile strength was investigated in this study. Parameters used for milling with a hammer impact mill were investigated to give different particle size milled extrudate. Mill screen type and aperture size were varied, along with mill rotor speed and extrudate feed rate to the mill. The results showed that reducing the mill screen aperture size, increasing the mill rotor speed and decreasing the extrudate feed rate led to a reduction in the milled extrudate particle size. Milling using a reduced screen aperture size caused a narrowing of the particle size distribution. A smaller milled extrudate particle size resulted in tablets of a higher tensile strength. This along with a narrowing of the particle size distribution resulted in more uniform tablets, hence less weak points for cracks to propagate, and a stronger tablet. More on tablet tensile strength