Ceolus MCC- Low levels of colored particles

Suppliers of pharmaceuticals and excipients face challenges in controlling technically unavoidable particles (TUPs) to prevent defects and protect brand reputation. Ceolus™, Asahi Kasei´s microcrystalline cellulose (MCC) products demonstrate exceptionally low levels of TUPs thanks to their comprehensive quality management approach. This includes strict raw material quality control, meticulous cleaning of manufacturing equipment, continuous in-process monitoring, the implementation of advanced particle removal technology, and thorough testing of the final products. Discover how Ceolus™ performs in minimizing defects in tablets caused by colored particles (excluding white and transparent particles) by checking out the article and data sheet below.

Reduction of technically unavoidable particles (TUPs) is one of challenges for pharmaceuticals and excipients suppliers because it may increase defective products or may create negative brand perception. On the other hand, TUPs are often found in microcrystalline cellulose (MCC) because of raw materials impurities or charring during the manufacturing process.

Our MCC products Ceolus™ shows low levels of TUPs because of our efforts including raw materials quality control, manufacturing equipment cleaning, in-process monitoring, installing particle removers and finished product testing.

We performed comparison of levels of colored particles (except white particles and transparent particles) in Ceolus™ MCC vs. other MCCs. This comparison clearly showed that Ceolus™ included lowest level of colored particles

Results

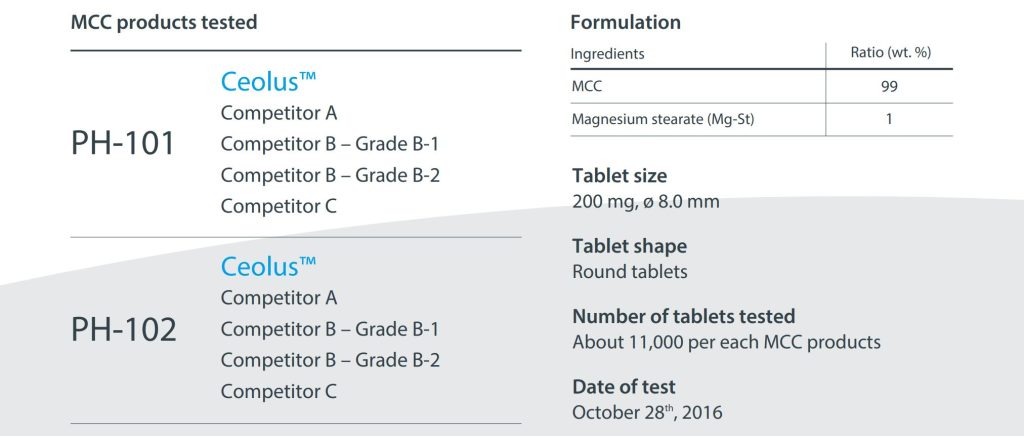

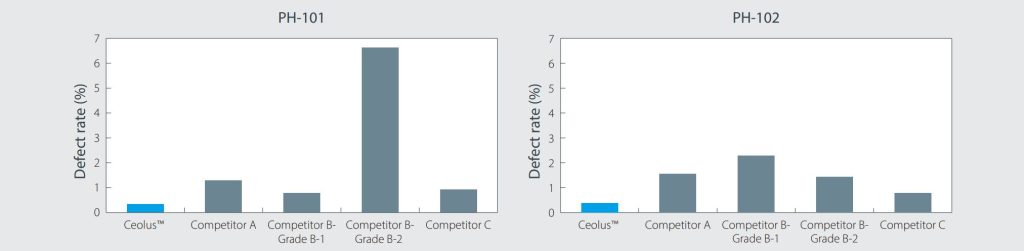

Defective tablets rate

Ceolus™ achieved the lowest level of defective tablets rate.

*Criteria of defective tablet

If one tablet includes 10 pixel or more colored particles, this tablet is recognized as the defective tablet.

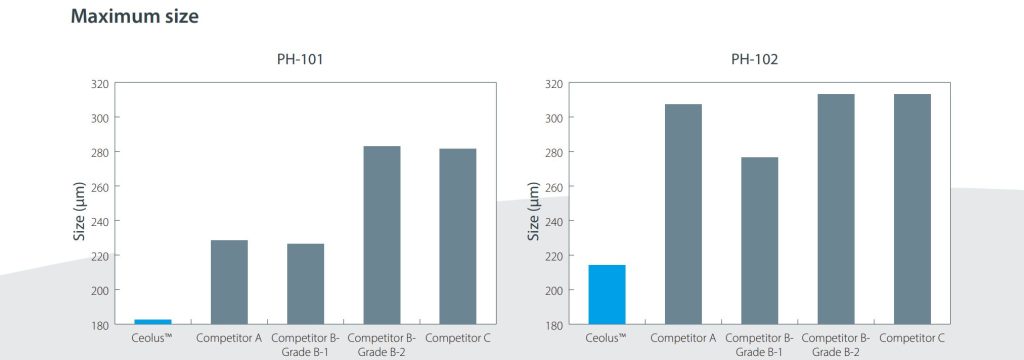

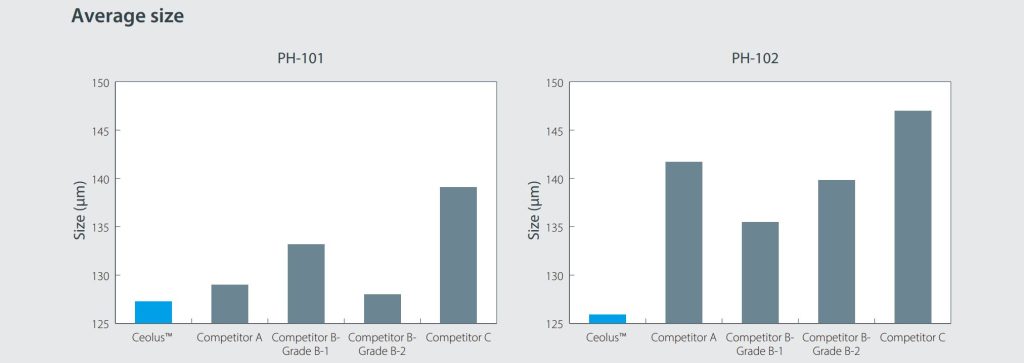

Size of colored particles in tablets

Tablets with Ceolus™ showed the lowest size of colored particles in tablets

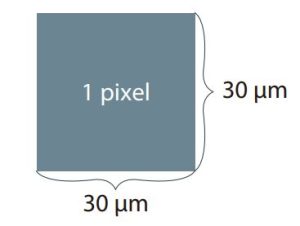

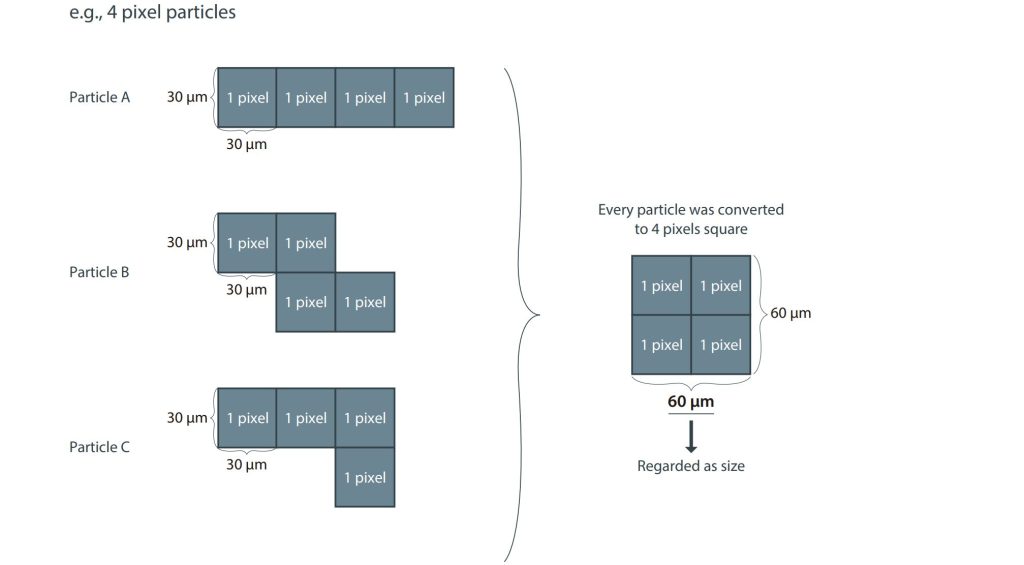

*How to calculate size

Total areas of colored particles detected were converted to one square and the length of one side on

this square was regarded as the size.

See the full technical brochure on “Ceolus – Low levels of colored particles” here

(click the picture to download the brochure)

Source: Asahi Kasei technical brochure “Ceolus – Low levels of colored particles“