DEM analysis of the influence of stirrer design on die filling with forced powder feeding

Abstract

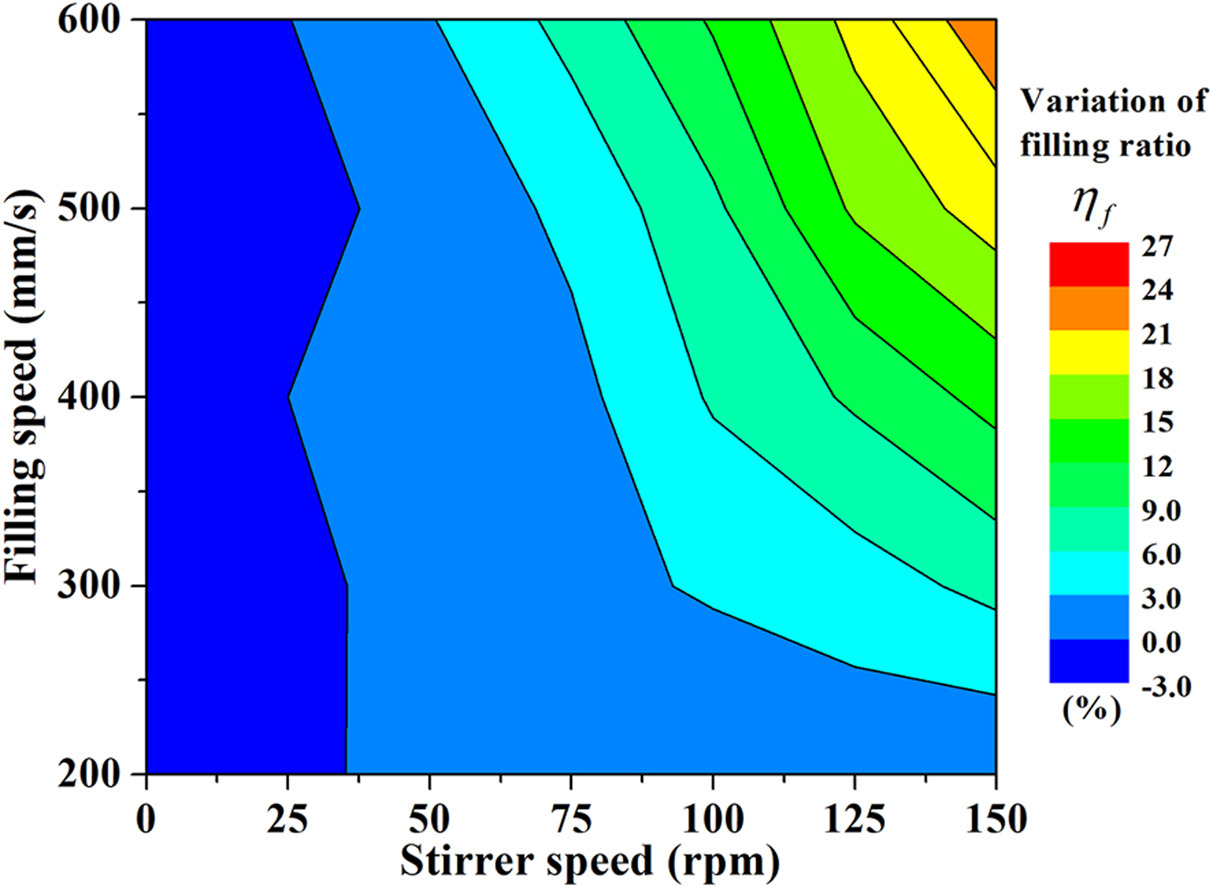

Die filling is a critical stage during powder compaction, which can significantly affect the product quality and efficiency. In this paper, a forced feeder is introduced attempting to improve the filling performance of a lab-scale die filling system. The die filling process is analysed with a graphics processing units (GPU) enhanced discrete element method (DEM). Various stirrer designs are assessed for a wide range of process settings (i.e., stirrer speed, filling speed) to explore their influence on the die filling performance of free-flowing powder. Numerical results show that die filing with the novel helical-ribbon (i.e., type D) stirrer design exhibits the highest filling ratio, implying that it is the most robust stirrer design for the feeder configuration considered. Furthermore, die filling performance with the type D stirrer design is a function of the stirrer speed and the filling speed. A positive variation of filling ratio (ηf>0%) can be ensured over the whole range of filling speed by adjusting the stirrer speed (i.e., increasing the stirrer speed). The approach used in this study can not only help understand how the stirrer design affects the die filling performance but also guide the optimization of feeder system and process settings.

Conclusion

In this study, a forced feeder is introduced to improve the filling performance of a lab-scale die filling system. The filling behaviour for VIVAPUR® MCC Spheres 350 is numerically analysed. Various stirrer designs are evaluated at a wide range of process settings (i.e., stirrer speed, filling speed) on their influence on the die filling performance.

Read more here

Chao Zheng, Edward Yost, Ariel R. Muliadi, Nicolin Govender, Ling Zhang, Chuan-Yu Wu, DEM analysis of the influence of stirrer design on die filling with forced powder feeding, Particuology, 2023, ISSN 1674-2001, https://doi.org/10.1016/j.partic.2023.08.018.

See the webinar:

“Fast Track development of Biphasic nano-dexamethasone Pellets using galenIQ™”, 12 October 2023:

Get more information & register here for free: