Extrusion for pharma applications: An update

This paper aims to give an overview of our current research and development on hot-melt extrusion (HME) for pharmaceutical formulation and drug delivery. Unfortunately, a large percentage of marketed drugs (40%) and those in the development pipeline (90%) are poorly water soluble.

We use a few examples to show that solubility of APIs can be drastically improved by using HME to mix them with different biocompatible polymers and playing with the various process parameters (extrusion temperature, screw speed, screw configuration, etc.).

The advantages of this technique are then presented as well as the further development needed to make this process fully industrial for pharmaceutical purposes.

Download the full article as PDF here SPE Polymers – 2023 – Gallas – Extrusion for pharma applications An update

or read it here

Excipients used in the study besides other: Soluplus, Kollidon 12 PF, Kollidon 30, Kollidon® 17 PF, Kollidon® VA 64, Klucel® LF, Affinisol, Eudragit RL, Eudragit L, Eudragit RS, Eudragit E PO

Rondol Industrie, Nancy Cedex, France, Institut Jean Lamour, UMR 7198 CNRSUniversité de Lorraine, Nancy, France, Extrusion for pharma applications: An update, Received: 30 August 2022, DOI: 10.1002/pls2.10081

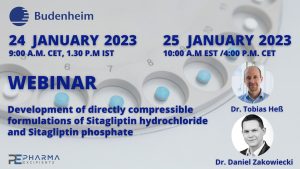

Our next webinar:

For free registration and more information click on the picture below or here: