Correlating Granule Surface Structure Morphology and Process Conditions in Fluidized Bed Layering Spray Granulation

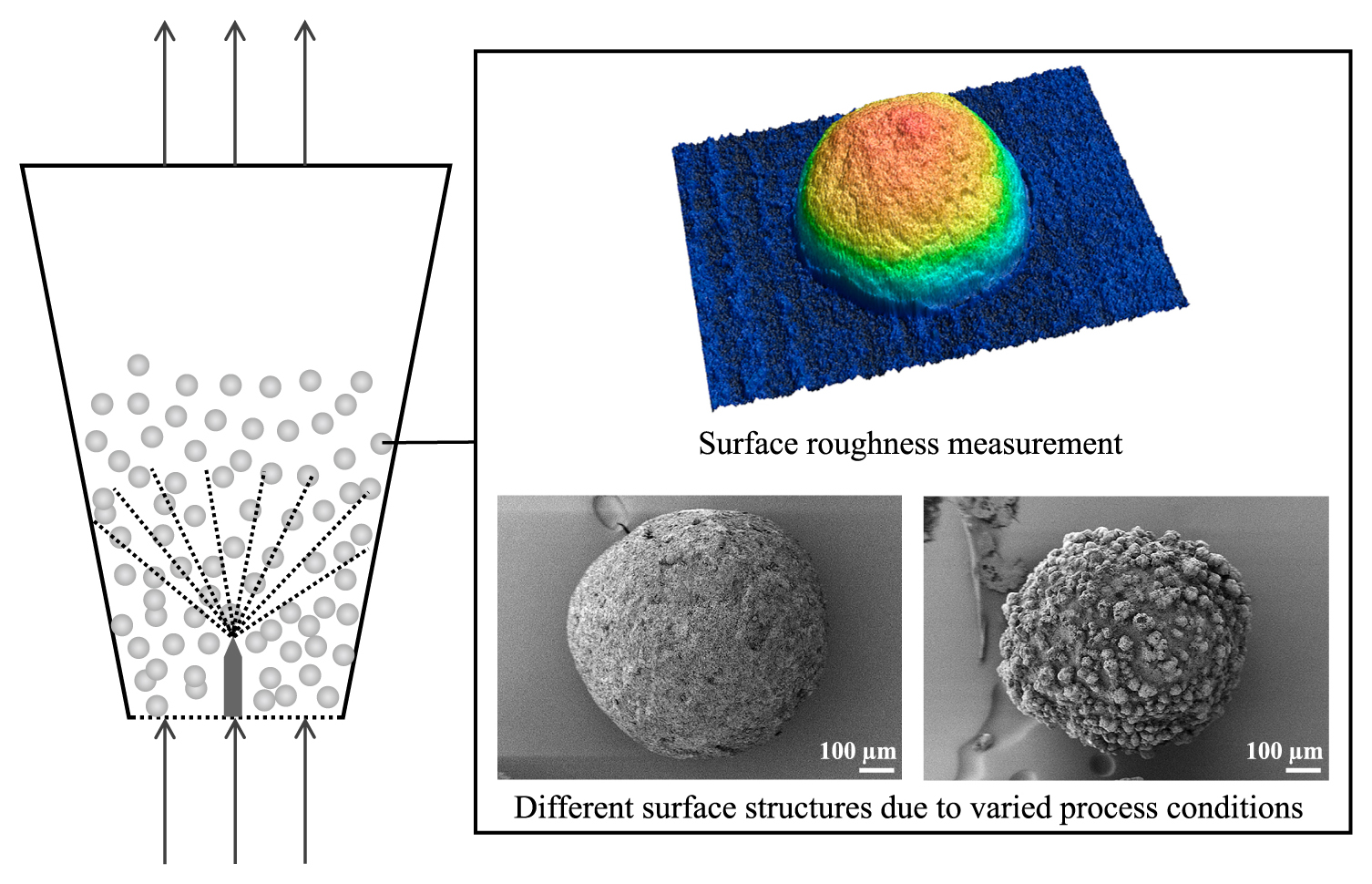

A workflow for developing a multidimensional, linear correlation between the process conditions during fluidized bed spray granulation and the surface morphology of the resulting granules is presented. Spray coating experiments with Cellets®500 particles and sodium benzoate solution were performed in a lab-scale fluidized bed varying liquid spray rate, fluidization air flow rate, fluidization air temperature, spray air temperature and spray atomization pressure.

To characterize the surface structure, the surface roughness of the coated particles was quantified using confocal laser-scanning microscopy. The roughness was correlated to the process conditions, and the resulting correlation was rigorously analyzed for the importance and co-linearities of the individual process parameters using a principal component analysis. The surface roughness is strongly dependent on the spray rate of the coating solution, the fluidization air temperature and the atomization pressure at the nozzle.

In general, wet process conditions and large droplets with a low initial velocity favor the formation of particles with a rough surface structure, while dry conditions and fine droplets with a high velocity result in granules with a smooth and compact coating layer.

Download the full article as a PDF here or read it here

Article information: Maike Orth, Paul Kieckhefen, Swantje Pietsch, Stefan Heinrich, Correlating Granule Surface Structure Morphology and Process Conditions in Fluidized Bed Layering Spray Granulation, KONA Powder and Particle Journal, Article ID 2022016, [Advance publication] Released September 25, 2021, Online ISSN 2187-5537, Print ISSN 0288-4534, https://doi.org/10.14356/kona.2022016, https://www.jstage.jst.go.jp/article/kona/advpub/0/advpub_2022016/_article/-char/en