HPMCP – Cellulose derivative for enteric coating by Shin-Etsu

HPMCP grades

Features

- Suitable for solvent coating system. As co-solvents, mixture of ethanol and water (80/20 w/w%) or mixture of acetone and water (95/5 w/w%) are recommendable.

- Relatively stable, due to less hydrolysis.

- Available as a solid dispersion carrier for solubility enhancement

According to the disintegration test method, dissolution time was measured for cast film from organic solvent:

- thickness: 100 μ m; size: 10 x 10 mm

- 〜 pH 5.6: USP Phthalate buffer

- pH 5.8 〜: USP Phosphate buffer

History of HPMCP (Hypromellose phthalate) at Shin-Etsu

Shin-Etsu was established in 1926 in Japan and employees more than 20 thousand people worldwide. Since the introduction of HPMCP (hypromellose phthalate USP/NF, JP, EP) in 1971, it has proved its value in enteric coating. HPMCP is a versatile coating material, it can be used for the enteric coating of tablets, pellets and capsules.

The enteric coating was developed in the 1940s to act as a barrier to protect drugs with low acidic stability from degradation by gastric acid or to protect gastric mucosa from irritating drugs. Moreover, it allows to deliver drugs optimally absorbed in the small intestine in a most concentrated form in this specific region of the digestive tract. HPMCP is also suitable for solid dispersion technologies.

General Product Information

HPMCP as enteric coating agent is insoluble in acidic environment like in gastric juice but dissolves immediately after the transfer of enteric coated tablets to the small intestine, as example. It is prepared from highly purified pulp, a widely distributed natural material, in our manufacturing site in Japan. The product is packed in 25 kg fibre drums with double polyethylene inner bags.

The chemical structure is a monophthalic acid ester of hypromellose dissolving easily in different organic solvents into a clear solution whereas the most recommended solvents to be used are ethanol/water or isopropanol/water combinations. The enteric coating solutions can be applied on tablets, capsules or pellets.

The film obtained with HPMCP is showing very good mechanical properties and mostly no plasticizer is needed in the formulation.

pH dependent disintegration of HPMCP

The threshold pH value for rapid disintegration of hypromellose phthalate can be controlled by varying the phtalyl content on the hypromellose backbone. HPMCP contains a carboxyl (phtalyl) group but its backbone structure is a water-soluble polymer. The phthalyl group defines the soluble nature of HPMCP, which is insoluble in water due to its hydrophobicity and soluble in weak acid to neutral medium.

Two types of HPMCP with different pH-solubilities, HP-55 and HP-50, are available. HP-50 disintegrates at pH 5.0 and HP-55 at pH 5.5 respectively. Moreover, HP-55S, a special type of HP-55, was introduced which is distinguished by:

- higher molecular weight

- greater film strength

- higher acid resistance properties.

An appropriate grade of HPMCP for particular purposes should be selected application-specific.

HPMCP is well established in several pharmaceutical products going from proton pump inhibitors to antibiotics and enzymes in form of enteric coated tablets or pellets.

In the recent years, besides enteric coating and driven by the need of improving the solubility of active ingredients, HPMCP is used as matrix polymer for amorphous solid dispersion systems developments.

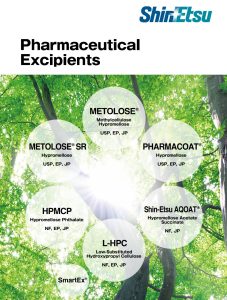

See the full brochure on “Pharmaceutical Excipients by Shin-Etsu” here

(find more on PHARMACOAT® on page 1, click the picture to download the brochure)

Source: Shin-Etsu, brochure “Pharmaceutical Excipients by Shin-Etsu”