METOLOSE® – Binder and Thickening Agent

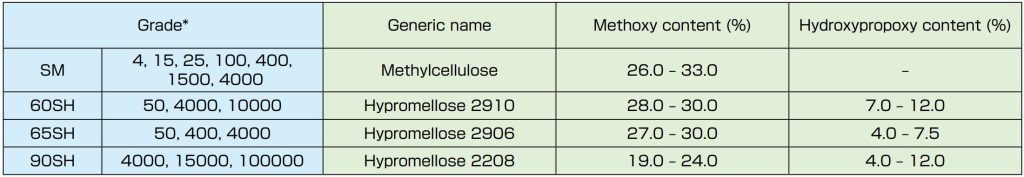

METOLOSE® grades

Water soluble cellulose ethers produced in Japan since 1962

Features:

- Non ionic and water soluble polymer with various viscosity.

- Applicable as film strips and dispersant of liquid formulation.

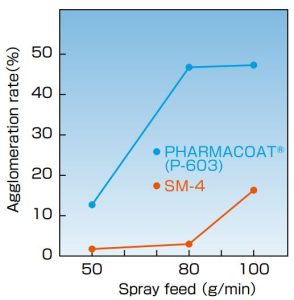

- SM-4 is recommendable for pellet coating as it is less sticky. The thermal gelling helps to prevent agglomerations during the coating process even at the higher spray speed.

Pellets which were extruded from 1.0 mm- diameter die were coated with 7% aqueous solution of SM-4 and the result was compared with PHARMACOAT® 603 (P-603) in fluidized bed granulator. The ratio of agglomerated pellets was analyzed from the weight retained on #16 sieve, when the spray speed was changed from 50 g/min to 100 g/min.

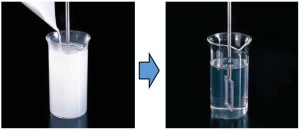

How to dissolve METOLOSE® in water

Adding the METOLOSE® powder directly into cold water can be challenging, as lumps can easily be formed due to the incomplete wetting of the powder.

One method to avoid the lump formation is to take the advantage of the insolubility of hydroxyl propyl methyl cellulose in hot water (>70 °C). After cooling down, the hydroxyl propyl methyl cellulose hydrates and dissolve fully. The hydration temperature depends on the substitution grade of hypromellose. For the METOLOSE® SM types, this temperature should be below 20 °C, preferably less than 5 °C, to guaranty the full dissolution of the particles. For the METOLOSE® 60SH, 65 SH and 90SH the temperature should be below 40 °C and ideally less than 10 °C. Thus, a cooling bath is recommended for the preparation of the hypromellose solutions generally.

METOLOSE® can be dissolved in organic solvents as well. Typical examples are a combination of ethanol and water or isopropanol and water.

Properties of solutions

Hypromellose solutions are stable over a wide pH range, going from pH 3 to pH 11.

METOLOSE® consists of hydrophilic and hydrophobic groups, and thus can be considered as well as a non-ionic surfactant. This attribute provides function such as protective colloid to stabilize emulsions, suspensions or foams. The surface activity will depend on the substitution type. The lowest surface activity is obtained with the METOLOSE® grade 60SH, which makes it a good candidate for artificial tears formulations, for example.

See the full brochure on “Pharmaceutical Excipients by Shin-Etsu” here

(find more on PHARMACOAT® on page 1, click the picture to download the brochure)

Source: Shin-Etsu, brochure “Pharmaceutical Excipients by Shin-Etsu”