Nano-encapsulation of probiotics: Need and critical considerations to design new non-dairy probiotic products

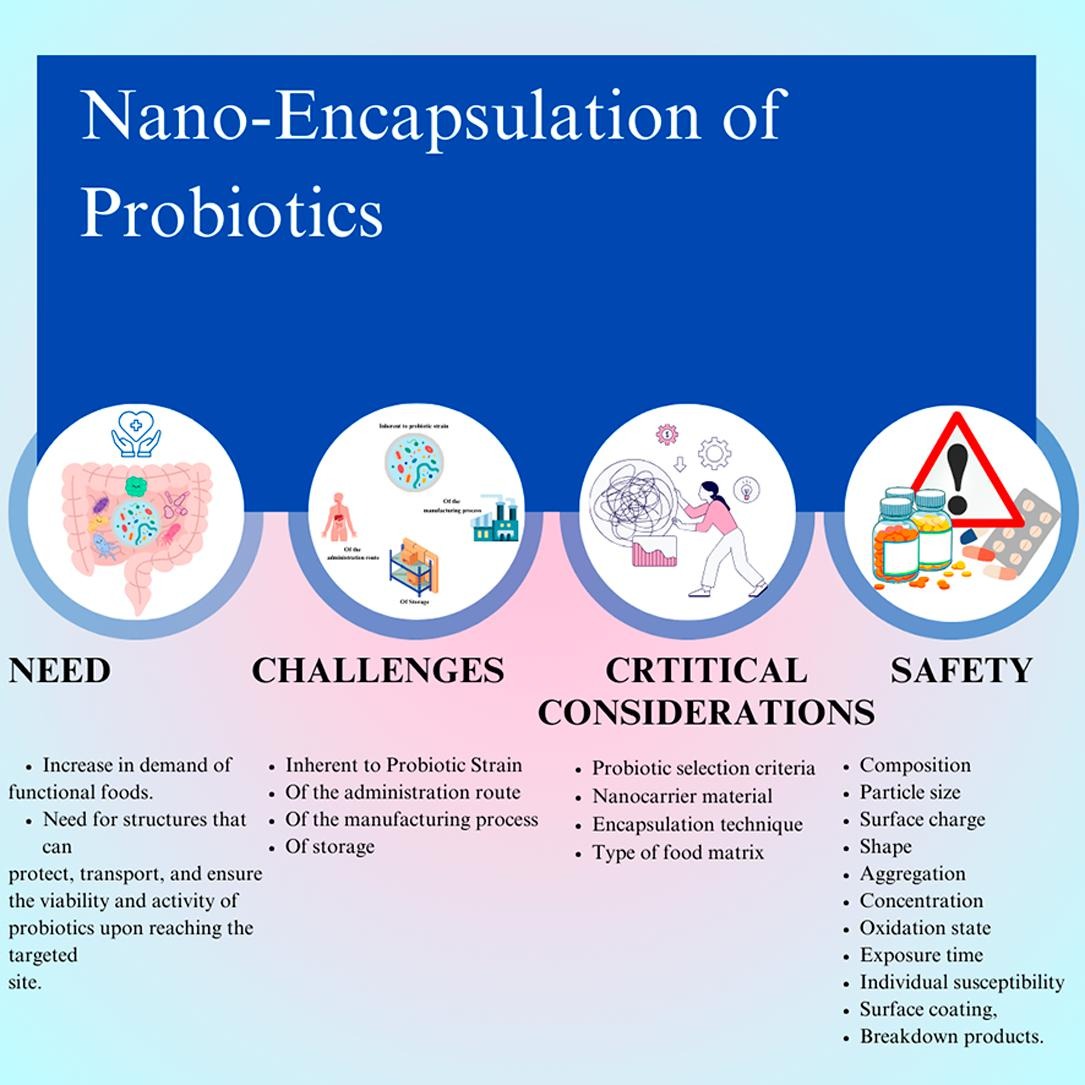

People worldwide need to improve their health or intention to control diseases more naturally through ingredients incorporated into foods and beverages, called functional foods. Functional foods include probiotic organisms and bioactive compounds incorporated into dairy and fermentable foods, whose consumption is recommended for various vulnerable groups linked to the need to stay healthy. The increase in the production of functional foods containing live probiotics has led to the development of new products, particularly of the non-dairy type, to counteract the disadvantages of dairy products, such as low digestibility, allergies, intolerance, increased cholesterol, and saturated fatty acids, or the consumer’s food preference, which impacts the consumer’s health. In this sense, the continuous development of non-dairy matrices through the application of nanotechnological strategies has had a significant impact on food science, providing nano-encapsulation systems for the transport, storage, and release of probiotic organisms, preserving their properties to exert their beneficial effects without affecting the sensory characteristics of the product.

Highlights

- Nanoemulsions are the commonest alternative to incorporate probiotics into non-dairy foods.

- Natural polymers are sustainable alternatives to develop non-dairy probiotic matrix.

- Encapsulation of probiotic strains improves the survival of cells in food matrices.

- Encapsulation protects the probiotic strains from harsh conditions.

- Encapsulation allows the delivery of probiotics through non-dairy foods.

This paper addresses recent advances in non-dairy matrices for probiotic strains, pointing out their advantages and limitations according to the characteristics of the matrix and the encapsulation techniques used. Considerations are presented to design non-dairy matrices based on nano-systems that allow obtaining quality products with nutritional value and high bioavailability, that increase viability, protect from factors such as pH and temperature, improve stability for bioactive compounds, and decrease adverse interactions between food components while acting as controlled release systems. Additionally, toxicological aspects and the need to continue toxicity testing for nano-systems intended to be used as non-dairy matrices in food, even when dealing with raw materials recognized as non-toxic, are pointed out, considering that each nanosystem presents different properties. As research and the use of non-dairy matrices for probiotics progresses, it may contribute to mitigating environmental damage.

Chapter 7.3. Polymeric systems

Polymeric systems play a crucial role in developing probiotic-based products in food and non-food compounds (Asgari et al., 2020). A polymeric-based transporter involves employing polymers to create a vesicular system, where probiotic cells are encapsulated within a reservoir protected by a shell. The core of this system may consist of hydrophilic or lipophilic substances (Manickam & Ashokkumar, 2014). There is a diverse range of polymers utilized for the encapsulation of probiotics, broadly categorized into naturally derived polymers such as pectin, chitosan, guar gum, gellan gum, dextran, cyclodextrin, alginates, xanthan gum, whey protein, and inulin, among others. Additionally, synthetic polymers like Eudragit L 100, Eudragit S 100, Hydroxypropyl ethylcellulose phthalate 50 or 55, and cellulose acetate trimellitate are also used (Vandamme et al., 2016, Asgari et al., 2020). When selecting a polymer for probiotic encapsulation, factors such as neutrality to the probiotic strain, processability, biodegradability, and biocompatibility are crucial considerations (Asgari et al., 2020). In the context of polymeric systems, probiotic cell suspensions are mixed with the chosen polymer (Mokhtari et al., 2019, Nami et al., 2020).

The encapsulation of probiotic cells within polymeric systems has been shown to significantly enhance the survival and viability of probiotic products during storage. Additionally, when utilized as stabilizers, polymeric systems can augment viscosity and prevent syneresis in lactic products (Huq et al., 2013). Numerous studies have provided evidence that strains such as L. acidophilus, Bifidobacterium spp., Lactobacillus lactis, Lactobacillus bulgaricus, and Lactobacillus rhamnosus can effectively withstand and survive harsh acidic conditions when protected within biopolymeric systems. To optimize probiotic resistance and increase cell survival through polymeric-based encapsulation techniques, factors such as the probiotic strain, capsule size, and the number of membrane coatings must be carefully considered (Hansen et al., 2002, Huq et al., 2013, Asgari et al., 2020).

Polymeric encapsulation systems are promising for delivering probiotic cells in non-dairy food products. For instance, Sivudu and Cols., 2016 encapsulated various probiotic strains, including Saccharomyces boulardii, Lactobacillus plantarum, Lysinibacillus sphaericus, Lactobacillus fermentum, and Lactobacillus casei, within alginate-coated chitosan beads incorporated into tomato and carrot juices. The encapsulation showed higher viability of cells compared to free cells when stored at 4 °C. Similar positive results were reported by Gandomi and Cols., 2016 and Praepanitchai and Cols., 2019, who encapsulated Lactobacillus rhamnosus GG and Lactobacillus plantarum, respectively, using mixtures of sodium alginate, inulin, chitosan, and soy protein isolate, and incorporated them into apple and mango juices. The incorporation of probiotic cells in these beads proved beneficial for cell survival. The application of polymeric encapsulation systems extends to bakeries (Seyedain-Ardabili et al., 2016) and meat products (Pérez-Chabela et al., 2013), where these systems demonstrate the potential to ensure the survival of probiotic cells before, during, and after processing of these food matrices.

Download the full article as PDF here Nano-encapsulation of probiotics

or read it here

Jenny Arratia-Quijada, Karla Nuño, Víctor Ruíz-Santoyo, Beatriz Adriana Andrade-Espinoza, Nano-encapsulation of probiotics: Need and critical considerations to design new non-dairy probiotic products, Journal of Functional Foods, Volume 116, 2024, 106192, ISSN 1756-4646, https://doi.org/10.1016/j.jff.2024.106192.