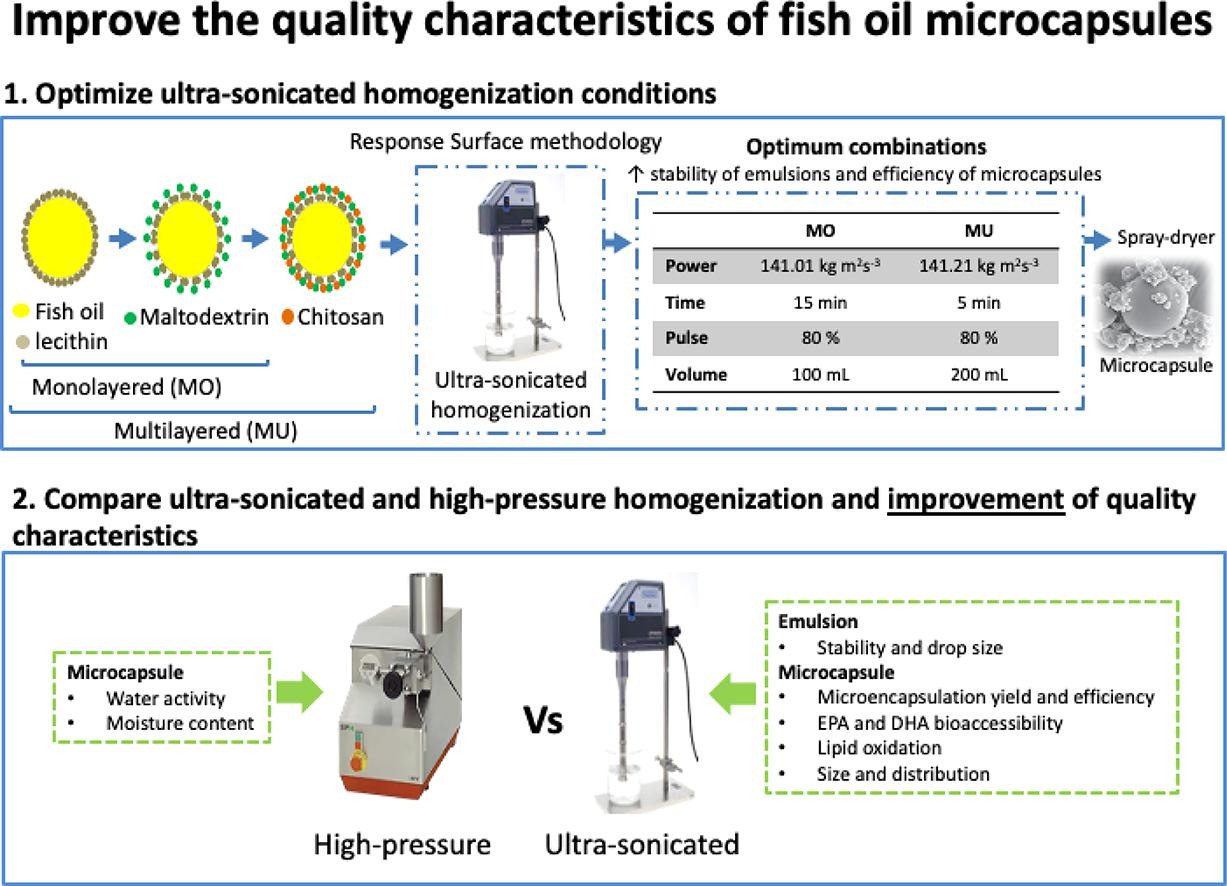

Optimization of ultra-sonicated homogenization conditions of fish oil emulsions to improve stability, efficiency and bioaccessibility of ω -3 microcapsules

This study aimed to improve the quality characteristics of fish oil microcapsules from monolayer and multilayer emulsions by optimizing the ultra-sonicated homogenization conditions to obtain a stable source of omega-3 fatty acids to add in food matrix. For that, a response surface methodology trial was firstly conducted to get optimum ultra-sonicated conditions that increase stability of emulsions and efficiency of microcapsules. Thus, optimum combinations of power of (141.01 and 141.21 kg m2/s3), time (15 and 5 min), pulse (80%) and emulsion volume (100 and 200 mL) were obtained for monolayered and multilayered emulsions, respectively. In comparison to homogenization by high-pressure, the use of ultrasounds improved most quality characteristics of emulsions (stability and drop size) and microcapsules (microencapsulation yield, total oil, microencapsulation efficiency, quantities and bioaccessibility of EPA and DHA, lipid oxidation, size, and distribution), especially in monolayered ones. It worth noting the increase in microencapsulation efficiency in multilayered and the improvement in emulsion stability and bioaccessibility of EPA and DHA in both types of microcapsules.

Download the full article as PDF here Optimization of ultra-sonicated homogenization conditions of fish oil emulsions to improve stability, efficiency and bioaccessibility of ω -3 microcapsules

or read it here

Materials

Fish oil from cod liver was kindly provided by Biomega Nutrition (Galicia, Spain). Soybean lecithin (Across Organics, Madrid, Spain), chitosan with 95 % of deacetylation (Chitoclear FG 95, kindly provided by Trades, Murcia, Spain), maltodextrin with a 12 % dextrose equivalent (Glucidex 12, kindly provided Roquette, Lestrem, France), and food-grade glacial acetic acid (Scharlau, Barcelona, Spain) were used for the preparation of the emulsions. Commercial buffer solutions (Crison, Barcelona, Spain) at pH 4.0 and 7.0 were used to calibrate the pH meter. Hydrochloric acid and petroleum ether (Scharlau) were used for the oil extraction of the microcapsules. 1-butanol and isopropanol (Scharlau) were used as solvents and 2-thiobarbituric acid (TBA, Serva, Heidelberg, Germany), trichloroacetic acid (Scharlau), and 2,6-di-tert-butyl-4-methylphenol 99% (BHT, Across Organics, Madrid, Spain) as reagents for the oxidative stability. Sulphuric acid, methanol, and hexane (Scharlau) were used for the transesterification of fatty acids. α-amylase from human saliva type IX-A, 1000–3000 U mg−1 protein (EC 3.2.1.1), pepsin from porcine gastric mucosa 3200–4500 U mg−1 protein (EC 3.4.23.1), porcine pancreatic lipase 350 U mg−1 protein (EC 3.1.1.3) and porcine bile extract (EC. 232–369-0) (Sigma-Aldrich, Madrid, Spain) were used for the simulated digestion and sodium chloride, potassium chloride, monopotassium phosphate, sodium bicarbonate, magnesium chloride hexahydrate, ammonium carbonate, calcium chloride tetrahydrate (Sigma-Aldrich) were used as electrolytes in simulated salivary, gastric, and intestinal fluids; sodium hydroxide and hydrochloric acid (Scharlau) were used to adjust the pH.

Juan Carlos Solomando, Teresa Antequera, Trinidad Perez-Palacios, Evaluating the use of fish oil microcapsules as omega-3 vehicle in cooked and dry-cured sausages as affected by their processing, storage and cooking, Meat Science, Volume 162, 2020, 108031, ISSN 0309-1740, https://doi.org/10.1016/j.meatsci.2019.108031.