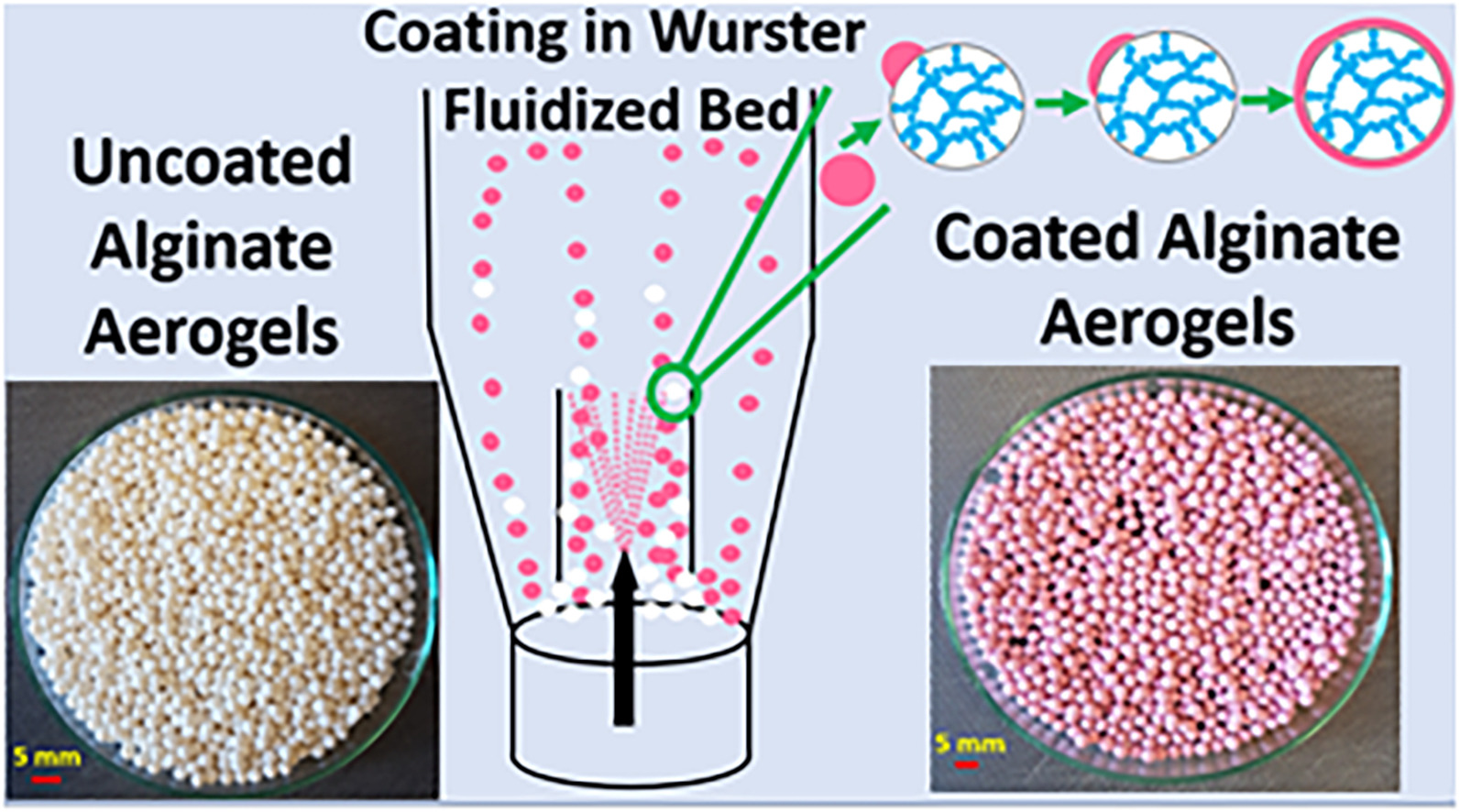

Protective coating of highly porous alginate aerogel particles in a Wurster fluidized bed

Alginate aerogel particles were successfully coated with a copovidone and hydroxypropyl cellulose based polymer in a Wurster fluidized bed. The results strongly indicate that the pores of aerogels were not damaged during the process. Several sets of experiments were conducted at three different temperatures and atomizing air pressures. Coating time for all the runs ranged from 5 min to 40 min and the coating thickness ranged from 12.4 ± 4.6 μm to 170.6 ± 43.3 μm.

Highlights

- • Alginate aerogel particles were successfully coated in a Wurster fluidized bed.

- • The highest coating layer thickness was 170.6 ± 43.3 μm.

- • Effects of temperature and atomizing pressure on coating thickness were studied.

- • Coating surface morphology changed with both temperature and atomizing pressure.

- • Rheology of coating solution governed spreading and adhesion of coating droplets.

Bed temperature led to significant changes in coating thickness whereas both bed temperature and atomizing pressure affected coating layer surface morphology. The smoothest coating layer surface and the highest coating efficiency which was 69.2 ± 0.4% with a linear increase in coating thickness were achieved at 50 °C with 1.7 bar atomizing pressure due to moderate polymer viscosity and storage modulus and high coating solution droplet velocity with a narrow droplet size distribution.

Işık Sena Akgün, Enis Demir, Murat Işık, Nadin Ekmekçiyan, Erkan Şenses, Can Erkey,

Protective coating of highly porous alginate aerogel particles in a Wurster fluidized bed,

Powder Technology, 2022, 117331, ISSN 0032-5910,

https://doi.org/10.1016/j.powtec.2022.117331.