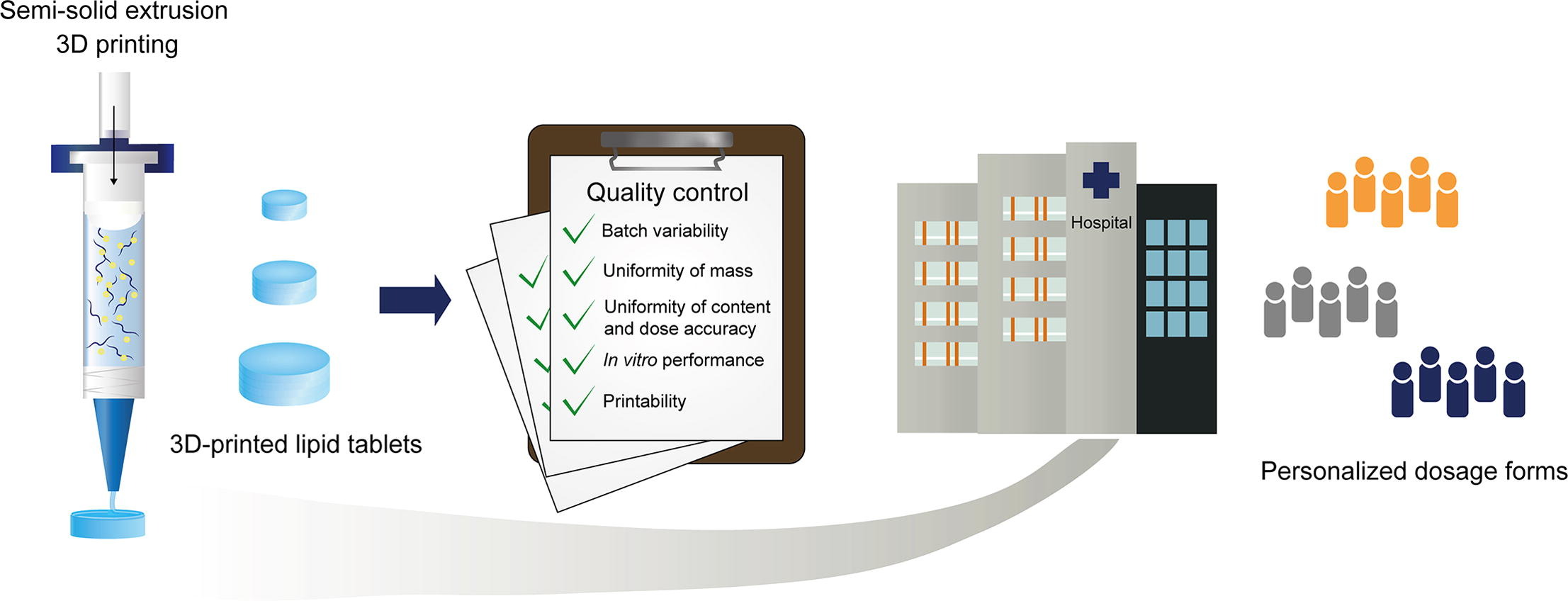

Quality attributes for printable emulsion gels and 3D-printed tablets: Towards production of personalized dosage forms

3D-printing technology offers a flexible manufacturing platform with the potential to address the need of personalized dosage forms. However, quality aspects of such small-scale, on-demand production of pharmaceutical products intended for personalization is still limited. The aim of this study was therefore to study critical quality control attributes of tablets produced by semi-solid extrusion (SSE) 3D printing from emulsion gels incorporating a poorly water-soluble drug. Quality attributes for both the printable emulsion gel and the printed dosage forms were assessed. The emulsion gel was shown to be printable with accurate dosing for at least one month of storage at 4 °C. Tablets were 3D printed in different sizes and a correlation, R2 value of 0.99, was found between the wight and the drug content. The 3D-printed tablets complied with the mass and drug content uniformity requirements described in the European Pharmacopoeia.. Solid-state characterization of the tablets during short-term storage revealed no signs of crystallinity of the drug. Lastly, the drug release was unchanged after short-term storage of the tablets. This study demonstrates the potential of SSE 3D printing for personalized dosing of a lipid-based formulation strategy and discusses central quality attributes for the printable formulation and the 3D-printed dosage form.

Introduction

The concept of one-size-fits all in pharmaceutical conventional manufacturing of solid oral dosage forms is problematic. This is particularly true for the pediatric patient population group, where individualized dosing is often required and acceptability of solid oral dosage forms is challenging (Johannesson et al., 2022, Richey et al., 2017). Modifications of solid oral dosage forms, by e.g., splitting tablets into halves or smaller parts, result in an increased risk for sub-optimal dosing (Watson et al., 2018). The lack of appropriate solid oral dosage forms for children has contributed to the increased discussion about the need to produce personalized dosage forms. However, manufacturing of small batches of dosage forms for personalization requires a high production flexibility, which is not achievable with conventional pharmaceutical manufacturing used for large-scale production.

To realize the idea of personalization, 3D printing has been extensively explored for its potential to produce on-demand personalized dosage forms in a clinical setting (El Aita et al., 2020b, Goyanes et al., 2019a, Öblom et al., 2019, Seoane-Viaño et al., 2021b). 3D printing is a generic term for the deposition of a material in a layer-by-layer fashion to create a 3D object. Different 3D-printing technologies (e.g. powder-based, solidification of liquids, and extrusion-based methods) have been explored for pharmaceutical application (Seoane-Viaño et al., 2021b). The first 3D-printed drug product approved by the U.S. Food and Drug administration, Spritam, is produced using a powder based, drop-on-powder technique. Extrusion-based techniques, such as semi-solid extrusion (SSE) is another 3D-printing method that has gained extensive interest for pharmaceutical purposes. This 3D-printing technique makes use of gels or pastes and can be operated at low temperatures. SSE 3D printing has been employed for production of e.g., immediate and sustained release tablets, polypills, and orodispersible films (El Aita et al., 2019, Khaled et al., 2015, Öblom et al., 2019). SSE 3D printing has also been used in a clinical study to produce personalized dosage forms for pediatric use (Goyanes et al., 2019a).

In addition, 3D printing can be a valuable technology to address the pharmaceutical challenge of poorly water-soluble drugs (Wang et al., 2022). Increased lipophilicity of new drug compounds is a result of contemporary drug targets in drug discovery. However, drug solubility is crucial to achieve sufficient bioavailability and therapeutic effect for orally administered drugs. To circumvent low solubility, several formulation strategies have been developed, including e.g., amorphous solid dispersions and lipid-based formulations (LBFs) (Bergström et al., 2016, Williams et al., 2013). Recently, a drop-on-powder technique was used for 3D printing of amorphous high-dose oral dosage forms (Gottschalk et al., 2023). Material extrusion-based 3D printing has also been coupled with hot-melt extrusion to produce amorphous dosage forms (Kim et al., 2021). Direct powder extrusion, a relatively new 3D-printing technique, where a powder blend containing drug and excipients are extruded directly has recently been used to produce amorphous solid dispersion (Boniatti et al., 2021, Goyanes et al., 2019b, Racaniello et al., 2023, Sánchez-Guirales et al., 2021). LBFs have been subject to 3D printing, where extrusion-based techniques have been applied to produce lipid-based dosage forms for poorly water-soluble drugs (Awad et al., 2023, Barber et al., 2021, Johannesson et al., 2021, Vithani et al., 2019). Despite, recent attempts to use 3D printing to produce dosage forms for delivery of poorly water-soluble drugs most pharmaceutical research on 3D printing is still focused on water-soluble drug candidates.

The clinical potential of personalized 3D-printed dosage forms is high, not at least for SSE 3D printing, which offers a fairly simple and direct production platform. The printable formulation can be available in pre-filled disposable cartridges, reducing the risk of cross-contamination. Since low temperatures are used, SSE 3D printing can be applied to many active pharmaceutical ingredients including thermosensitive drugs. In addition, the excipients used are often listed as food-grade or GRAS (Generally Recognized as Safe) (Rahman and Quodbach, 2021, Seoane-Viaño et al., 2021a). Furthermore, SSE has demonstrated the capability of precise and accurate personalized dosing and production of drug combinations, i.e., polypills with tailored release properties (Cui et al., 2019a, Khaled et al., 2015). Clinical implementation of SSE 3D printing technology for production of personalized dosage forms, however, requires new regulatory and quality frameworks including 3D printer, printable formulation, and 3D-printed dosage forms (Parhi, 2021). Unlike the case of Spritam, where 3D printing is used for large-scale production, no standardized guidelines exist for on-demand and personalized production using 3D printing. Previous work has been carried out to evaluate SSE 3D printing based on quality recruitments described in the Pharmacopeia (Lafeber et al., 2021). However, due to the different nature and purpose of 3D printing, other studies have investigated the quality of SSE printed dosage forms compared to compounding techniques, which are regulated on a national level (Callede et al., 2022, Chachlioutaki et al., 2022, Öblom et al., 2019).

The regulatory challenges for 3D printing of personalized dosage forms remains. To address this, quality control aspects of both the printable formulation and the produced dosage form need to be studied with regards to the use of 3D printing for personalization of medicines.. Therefore, this study aimed to evaluate critical quality control attributes of lipid-rich tablets produced from emulsion gels using SSE 3D printing. This to further expand on the knowledge about quality aspects of different types of printable formulations, including lipid-based formulation strategies used for SSE 3D printing and the printed dosage form. A previously developed emulsion gel incorporating a poorly water-soluble drug, fenofibrate was used in this study (Johannesson et al., 2021). The quality control assessment was focused on both the printable emulsion gel and the 3D-printed lipid tablet. The quality testing was based on central requirements for solid oral dosage forms described in the European Pharmacopoeia (Ph. Eur.) including mass and drug content uniformity. Additional quality testing, including dose accuracy and printability was carried out with the purpose of quality aspects related to production of personalized dosage forms. This study thus provides information about quality aspects of SSE 3D printing of emulsion gels for production of personalized dosage forms.

Materials

Capmul MCM EP (mixed medium-chain glycerides) was kindly provided by Barentz ApS (Odense, Denmark) and Captex 355 EP/NF (medium-chain triglycerides) by Abitec (Janesville, USA). Ac-Di-Sol SD-711 (croscarmellose sodium) was donated by IFF Nutrition & Bioscience. Analytical solvents were purchased from VWR International (Spånga, Sweden). Fasted state simulated intestinal fluid (FaSSIF) powder was purchased from biorelevant.com (Croydon, UK). Fenofibrate (≤ 99.9%), Kolliphor EL (surfactant),…

Read more

Jenny Johannesson, Mingjun Wu, Mathias Johansson, Christel A.S. Bergström, Quality attributes for printable emulsion gels and 3D-printed tablets: Towards production of personalized dosage forms, International Journal of Pharmaceutics, 2023, 123413, ISSN 0378-5173,

https://doi.org/10.1016/j.ijpharm.2023.123413.