L-HPC – Multifunctional excipient for oral solid dose by Shin-Etsu

L-HPC (low-substituted hydroxypropyl cellulose NF, JP, EP) was developed by Shin-Etsu and first approved in 1977 as a disintegrant for tablets in Japan. New grades were developed during the last years in order to cover the needs for our customer having best solutions for individual applications.

As example, LH-B1 was launched in 2002, a non fibrous grade, recommended as dispersing aid for capsule filling. In addition to the conventional grades (LH-), NBD- grades which have improved characteristics such as particle shape and compressibility were introduced in 2011.

History of L-HPC

Structure

L-HPC is a non-ionic multi-functional excipient based on a cellulose backbone combined with a low amount of hydroxypropopyl groups.

Thus, L-HPC is not soluble in water but showing swelling properties in this media. Typical applications of L-HPC are anti-capping for tableting process, binder and disintegrant, stability enhancer of solid dosage forms. Several grades are available (see the table below) depending on the final application, focusing on the most common oral dosage forms: tablets, pellets and capsules.

Disintegrant, binder, anti-capping agent

Benefits and Applications of L-HPC

L-HPC used in immediate release tablets contributes to the optimisation of the formulations and can be seen as a problem solver. One of the benefits of L-HPC is linked to its non-ionic nature and absence of peroxide leading to a better stability of the drugs by avoiding interactions with active pharmaceutical ingredients (API).

Another advantage linked to its particle size and shape is to resolve “capping” issues, which is a typical problem in the tableting process. Several reports have highlighted that capping is caused by a high residual die-wall pressure during the tableting process. L-HPC reduces the residual die-wall force and ejection force during the tableting process.

Looking at the functionalities of the L-HPC in terms of swelling and especially the optimized compressibility of the NBD grades, it can simplify immediate release tablets formulation as only one excipient is needed to assure good tablet hardness and quick disintegration. Thus L-HPC is a key excipient for reducing the tablet size as it is the case for mini-tablets. Besides the direct compression, in case of poor powder flowability or low active content, a granulation step is needed to improve the flow of the tabletting mass.

L-HPC can be used during the wet or the dry granulation process. Roller compaction is a dry granulation technique. The powder blend requires sufficient binding to form a stable ribbon and larger granules with less fine powders after the milling step. L-HPC NBD-grades increase the binding properties of the roller compaction formulation. At the same time L-HPC acts as disintegrant ensuring the quick disintegration of the roller compacted immediate release formulation.

As well as tableting, L-HPC is also applicable for pellet extrusion. Micronized grades (typically LH-31) are best suited for this application because smaller particles can easily pass through the screen. L-HPC provides wet mass with a “buffer effect” where the wet mass accepts a wider range of water content. L-HPC plasticizes wet mass and shows greater productivity (extrusion speed and yield). The final pellets show quick disintegration and better friability compared with non-L-HPC formulations.

For the capsule filling, the swelling property of L-HPC will actively contribute to improve the disintegration and dissolution of the cake formed during the capsule filling process. L-HPC has 9 variations in physical and chemical properties and can be used for different application. In order to know which grade is more suitable for your application check our guide of application in the table below.

Features

- Water insoluble, swells in water and works as dual functional ingredient, disintegrant and binder for tablets and pellets.

- Suitable grade can be selected depending on process and API characteristics.

- Non-ionic polymer which has less interaction with API and better stability.

Anti-capping effect of L-HPC

Ethenzamide tablets were prepared with various ratio of excipients and friability test was implemented in accordance with USP method.

Technical Information regarding L-HPC

Shin-Etsu has more than 40 Technical documents available for L-HPC; such as:

- Dry Granulation/Roller Compaction with L-HPC

- Wet Granulation with L-HPC

- DC with L-HPC

- Bilayer Tablets – IR & SR

- Drug Layering with L-HPC

- Herbal/Extracts/Vitaminis formulations with L-HPC

- ODT with L-HPC

- Twin Screw Wet Granulation with L-HPC, among others…

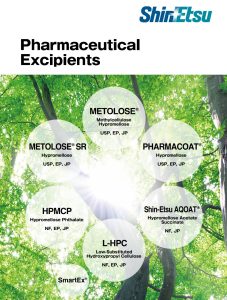

See the full brochure on “Pharmaceutical Excipients by Shin-Etsu” here

(find more on PHARMACOAT® on page 1, click the picture to download the brochure)

Source: Shin-Etsu, brochure “Pharmaceutical Excipients by Shin-Etsu”